Assembly Automation: Articulated vs SCARA Robots

Assembly automation involves using industrial robot arms to automatically construct products. Assembly robots are used in a wide range of industries including the automotive and electronic industries among many others. Articulated and SCARA robots are the two most common robot types used for assembly automation. Each offers their own strengths when correctly implemented. Choosing between the two will depend upon the specifics of your assembly application.When to Choose an Articulated or SCARA Robot for Assembly Automation

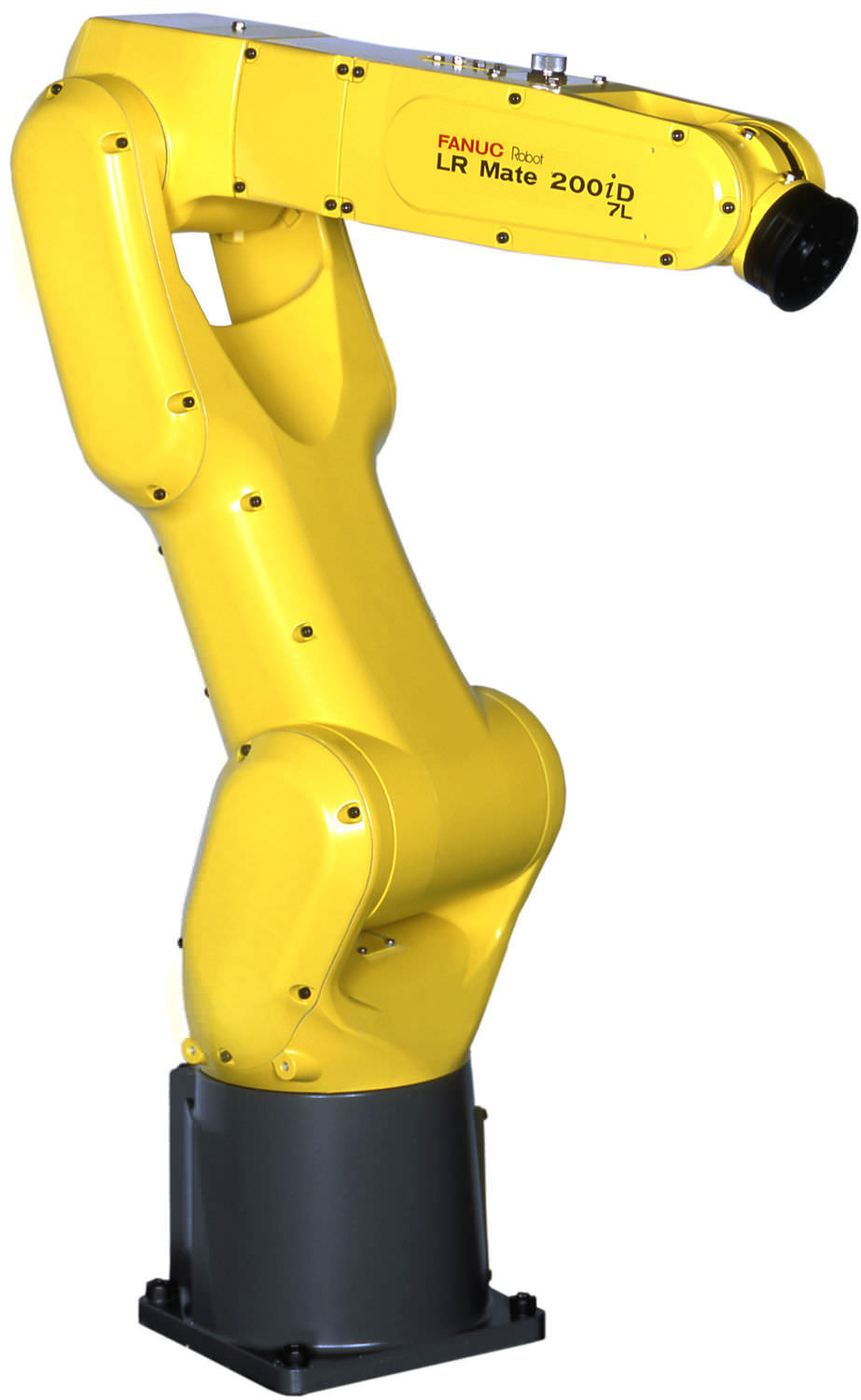

Below is a look at some of the key factors to consider when determining whether to automate an assembly process with either an articulated or SCARA robotic manipulator.- • Assembly Complexity - The complexity of your assembly will be a big factor for whether to automate with an articulated or SCARA robot. Complex assemblies should be automated with a six-axis articulated robot. The FANUC LR Mate 200ic has six degrees of freedom which allow it to approach parts from any angle which is needed when assembling complex workpieces. SCARA robots typically have three to four axes which limits their range of motion. The motion of their Z axis is rigid, making SCARA robot manipulators best for simple assembly tasks.

- • Speed - For high speed assemblies SCARA robots cannot be beat. SCARA assembly robots are some of the fastest, just behind delta robots. Their smaller size combined with fewer axes to control, allows them to operate at very fast speeds. Automating an assembly with the FANUC SR-6ia will significantly reduce cycle times. While articulated robots may not be as speedy as SCARA robots, automating with them will still be significantly faster than manual assembly.

- • Assembly Size - The size of your assembly process is another factor to consider. Articulated robots can automate small to large assemblies. While SCARA factory robots are limited to only automating small assemblies. In general, articulated robots tend to have longer reaches than SCARA robots. This provides them with a larger work envelope and the ability to work with bigger parts. Most SCARA industrial robotic arms have reaches under 1,000 mm which prevents them from being able to work with larger parts. However, for small assemblies or narrow workspaces they are ideal.

- • Accuracy - Automating with either an articulated or SCARA robot manipulator is going to lead to a more accurate assembly. However, SCARA robots are incredibly accurate and have the best repeatability out of any robot type. The fixed Z axis of the FANUC SR-12ia and other SCARA manufacturing robot arms prevents them from pivoting up and down during assembly. This allows them to achieve tolerances under 10 microns. While articulated robots typically have tolerances around 20 microns. For this reason SCARA robots have the edge on high accuracy assemblies.

- • Payload Requirements - Articulated handling robots are available in a variety of payload capacities. This allows them to automate light, medium, and heavy assembly applications. SCARA robots are only available in light payloads since they are small robots, this prevents them from automating any assembly process other than those that are light. If you are automating a heavier assembly then an articulated industrial robot arm such as the Motoman MH24 will be best.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling a used robot.