Advantages Vs. Disadvantages of Industrial Robots

Industrial robots are changing manufacturing and doing so in record numbers. Each year more robots are added to manufacturing floors and it’s easy to understand why as the advantages outweigh the disadvantages.

Advantages

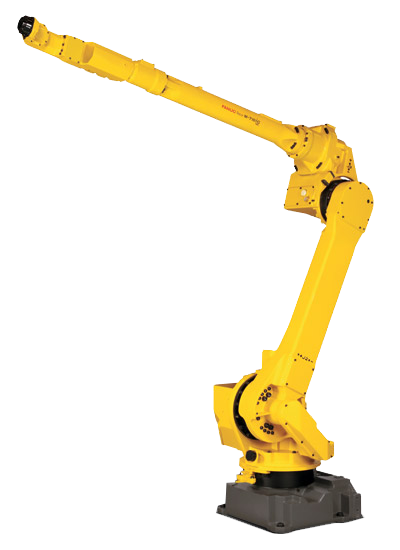

- Improved Worker Safety - Manufacturing jobs can be labor intensive and involve working in hazardous conditions, both of which can be detrimental to a worker’s health and safety. Automating manufacturing lines with industrial robots improves the overall safety of the facility. Robots are resilient machines that are more capable of handling repetitive, laborious work than humans. The FANUC R-2000ib/210F not only can handle heavy payloads but is also specially designed for tough work environments.

- Decreased Costs - Production and labor costs can both see a dramatic decrease through robotic automation. Industrial robots reduce the need for human interaction which helps to eliminate the chance of human errors that often result in wasted or scrapped materials and higher costs. On the labor side, costs are also cut as robots do not require a salary, paid time off, or benefits.

- Increased Productivity - Every manufacturer strives to increase their productivity rates. The more productive a production is, the more likely they will see an increase in profits. Increased productivity is obtainable through automation with industrial robots. Robots can handle larger workloads and are more efficient. A single FANUC M710ic/50 can do the same amount of work as up to four workers. Robots are also capable of operating for longer hours which boosts productivity as well.

- Better Product Quality - Accuracy and precision are needed in manufacturing in order to produce high-quality products. Articulated robots are designed to operate with the highest accuracy and precision repeatedly. Their controlled movements prevent errors from occurring or deviations from their programmed paths. Products as a result turn out uniform and high-quality with each cycle run.

- Shorter Cycle Times - Robots can operate at much faster speeds than human workers. They do not take breaks, pauses, or lose concentration in-between tasks. As a result, cycle times can be significantly reduced. Shorter cycle times contribute to an efficient manufacturing process. The FANUC LR Mate 200id can perform automated pick and place much quicker than a human.

- Reliability - Industrial robots operate with consistency. They do not hesitate between parts, deviate from their programmed applications, or lack focus. As a result, manufacturing processes become reliable with the occurrence of unexpected issues to be rare. Automating a welding process with a Motoman MA1400 will be overall more reliable than using manual welding.

Disadvantages

- Initial Cost - The initial cost of a robotic system can be steep and may be one of the biggest holdups for businesses deciding on whether or not to automate. However, in the long run robots will result in reduced manufacturing costs. Reduced costs combined with higher productivity rates will allow companies to capture their ROI relatively quickly, making robots a smart investment. Those concerned about purchasing costs should consider buying a used robot. Robots have a long lifespan and one of the biggest benefits of second-hand robots is their affordability.

- Replacement of Workers - Many believe industrial robots are displacing workers from their jobs. Robots taking jobs away from workers is one of the most common robot myths. In reality robots help to create more productive, skilled, and better paying jobs for workers. Positions such as operators, programmers, and engineers are all created and needed due to robotic automation.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.