Advantages of FANUC Spider Robots

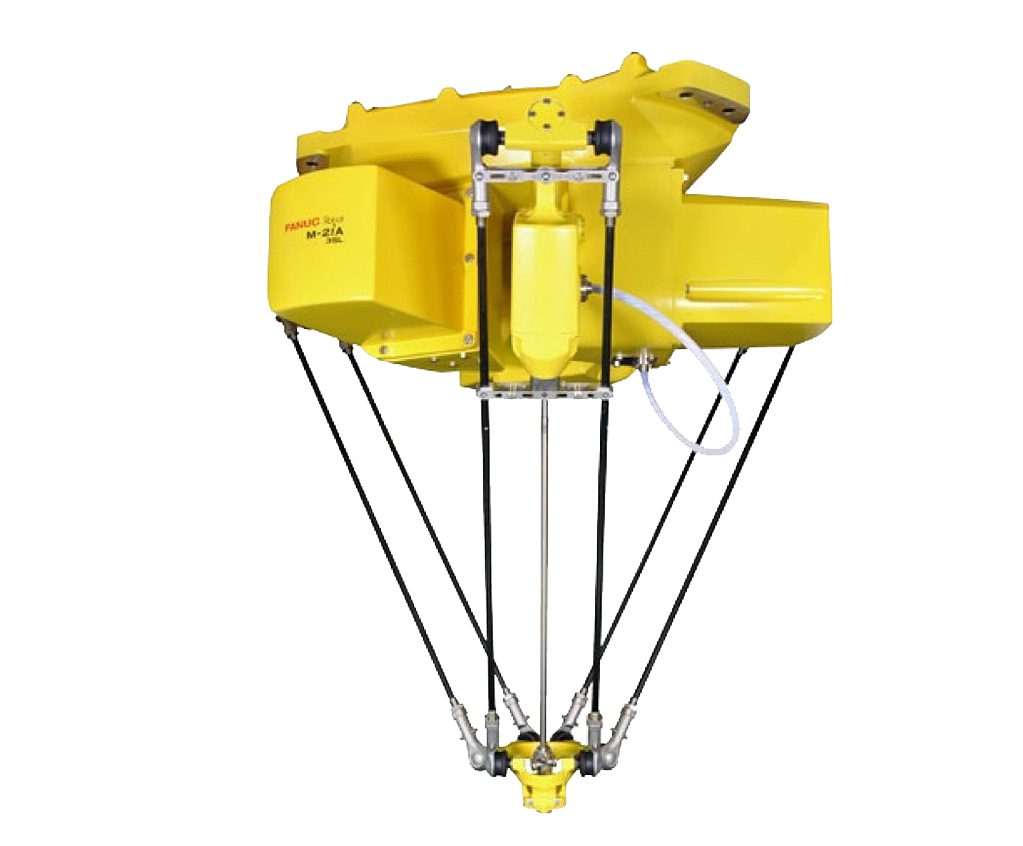

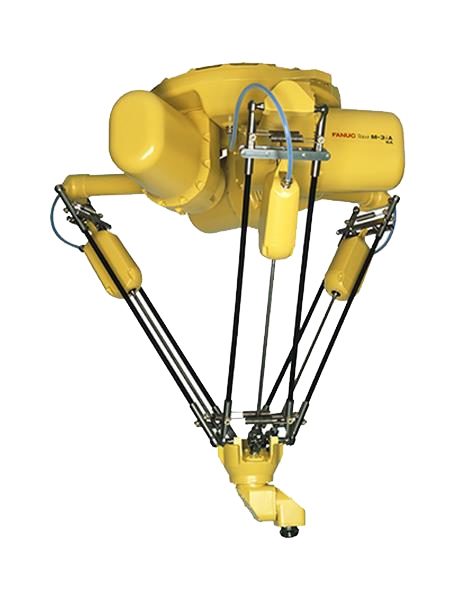

FANUC is one of the largest robotic manufacturers in the world. They produce a wide variety of industrial robots including articulated, gantry, SCARA, collaborative, and delta robots. Their delta robots are often referred to as the FANUC spider robots. There are three lines of spider robots, the M-1iA, M-2iA, and the M-3iA. Each line features a standard model with multiple variations also available. FANUC delta robots are ideal for automating high speed picking applications. While they may appear quite small, FANUC’s spider robots are still incredibly advantageous to automate with. The following is a list of their main advantages.

- • Speed - FANUC’s spider robots are some of the fastest industrial robots on the market. The delta style design allows for fast, agile movements from the FANUC M-1ia and the other spider robots. Their light weight arms, parallel axis connections, and motor placement allows these robots to operate at faster speeds than any other industrial robot arms. FANUC spider robotic manipulators are ideal for automating light payload and high speed applications. Cycle times will be significantly reduced with these robot manipulators.

- • Reduce Employee Injuries - FANUC spider robots are well suited for automating repetitive high-speed applications. These types of tasks can cause repetitive motion injuries for employees such as carpal tunnel, tendinitis, and muscle strains. Automating with the FANUC M-2ia removes workers from performing highly repetitive processes and reduces their risk of suffering from a motion injury. Fewer worker injuries means less disruptions to manufacturing, reduced worker compensation claims, and better employee satisfaction.

- • High Repeatability - FANUC spider robots feature high repeatability. They can perform the same task over and over without deviation, producing consistent results. Their high repeatability allows them to excel at repetitive applications like robotic pick and place. Each cycle is completed with the same accuracy and precision as the one before. Errors are reduced with the consistent operation of FANUC factory robots.

- • Size - Not every application will benefit for a standard sized industrial robotic arm. There are also many factories with minimal space to spare. The small size of the FANUC spider robots allows them to be easily integrated along production floors or in robotic workcells. With a compact footprint they can operate within narrow or confined work areas. They are also typically mounted overhead, allowing the space below them to remain free.

- • Higher Productivity - With incredibly fast operating speeds and lower cycle times, productivity rates will significantly increase with the FANUC spider industrial robot arms. FANUC’s spider robots can pick over 100 parts per minute resulting in greater throughput and higher productivity. In addition to fast speeds, FANUC spider robots can also run around the clock. The combination of fast operation speeds and twenty-four hour run times allows manufacturers to achieve hyper productivity.

- • Better Quality - Quality will also improve with the consistency, precision, and accuracy of FANUC’s spider robots. Their high repeatability ensures precise and accurate operation. This mitigates errors that hinder product quality. Parts are handled safely preventing them from becoming damaged. Not only does product quality improve with FANUC’s assembly robots but it becomes consistent and predictable.

Contact Robots Done Right in order to discuss selling a used FANUC industrial robot today.