Torch Mounting Options for Robotic Welding

There is a lot that goes into automating a welding process. The type of weld, workpieces, welding robot, robotic welding power source, wire feeder, torch, and safety equipment must all be considered for a successful transition to robotic welding. In addition to determining the equipment needed, users must also decide how to best arrange the welding equipment, including how to mount the welding torch. Users have two options when it comes to torch mounting options for robotic welding; through-arm and over-arm mounts.

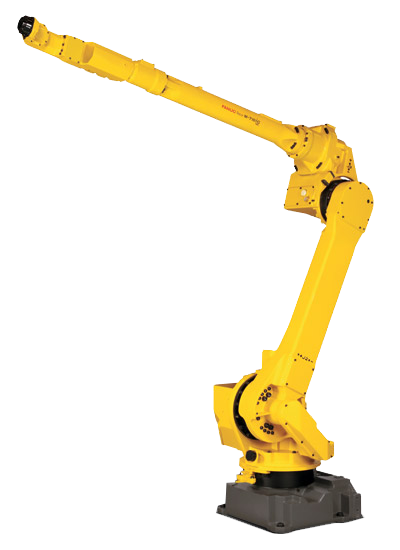

Through-arm torch mounting involves the internalization of torch cables through the six axis robot wrist and arm. Breakaway collision mounts and solid mounts may both be utilized for a through-arm setup. This is how a torch would be mounted on a FANUC Arcmate 100ic. Breakaway collision mounts help to prevent contact with objects, people, or other equipment with built-in collision sensors. These sensors will automatically turn the welding torch off should the neck of the torch come into contact with any objects besides the workpiece. This helps to reduce damage and accidents from occurring during the welding process.

Solid mounts are more popular for through-arm cabling since they do not require brackets and fixtures. Solid mounts allow for a simplified torch setup that is conducive for welding in narrow spaces or welding inside parts with tight tolerances. Many of today’s industrial robots already have built-in collision sensors, eliminating the need for shock sensors within the torch mount.

Solid mount through-arm torch cabling can help extend cable life. The torch cable is kept secure during operation, preventing excessive cable movement which can lead to premature wear and tear. In addition, cable interference is also prevented allowing for better welding reliability. Another benefit of solid mounts for through-arm setups is that repeatability is increased. Most newer used FANUC welding robots have the hollow wrist design. The FANUC Arcmate 120ic is designed to accommodate a through-arm torch cable setup.

Over-arm torch mounts were the original type of torch mount used for robotic welding. With this arrangement torch cabling runs over the robotic arm instead of through it. The FANUC Arcmate 120ib is a welding robot that can be integrated with an over-arm torch mount. As with through-arm mounting, both breakaway collision mounts and solid mounts can be utilized. Over-arm mounts allow for torch positioning in more complex angles, especially for narrow welds.

The main advantage of over-arm torch mounts is their ease of maintenance. Since the torch package is exposed instead of inside the arm, it is easier to access for maintenance or for any necessary repairs. However, having the cabling on the outside of the articulated robot may cause it to wear down more quickly. In addition, it is important the cable is the correct length as too long of a cable could lead to it becoming caught or interference during welding.

With either mounting option it is important to ensure a solid machine surface with as few bolts as possible. Having fewer bolts or components allows for higher repeatability and a more secure torch mount. Having high and consistent torch repeatability allows for maximum reliability and prevents the need to rework the mount setup. This allows for increased welding productivity.