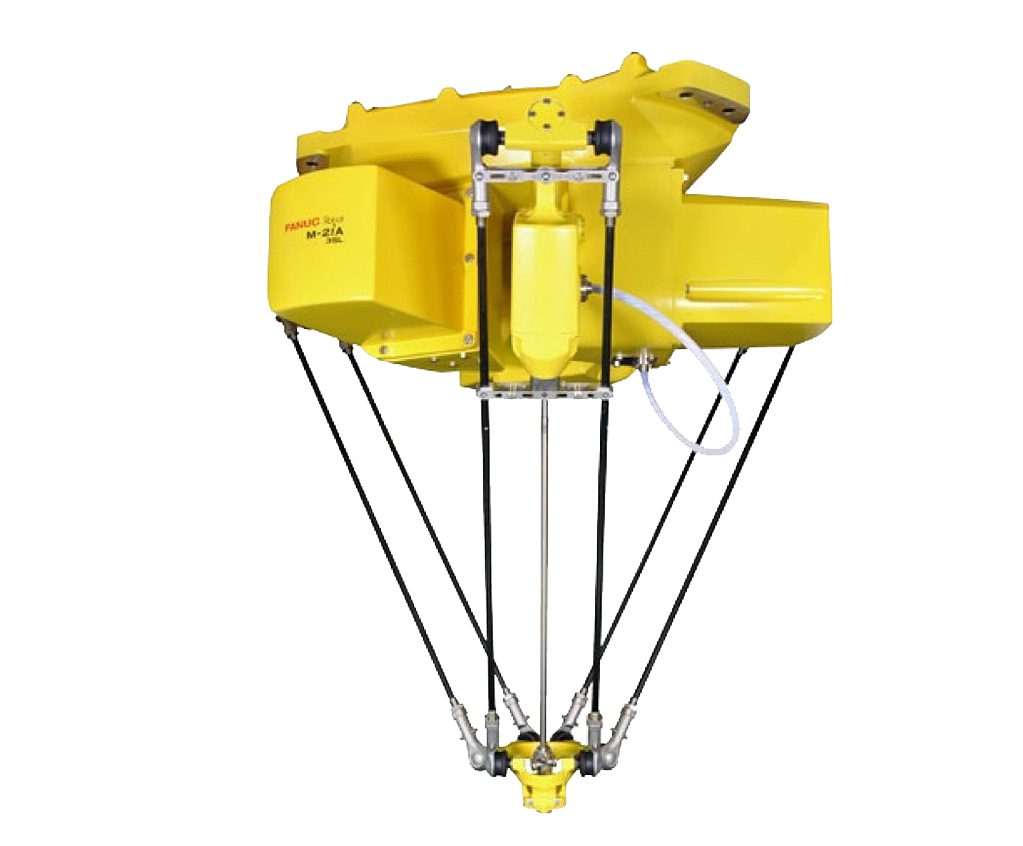

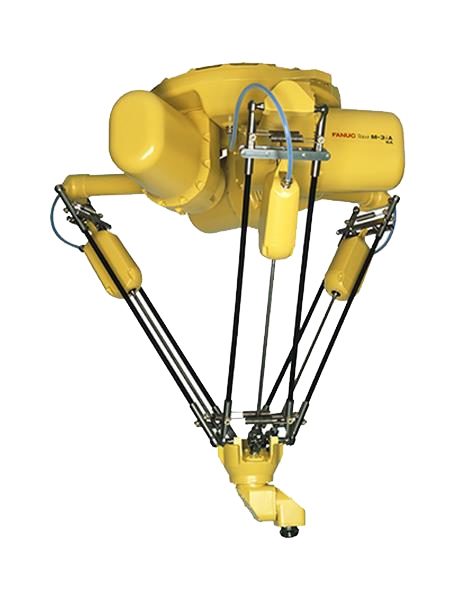

Delta robots are one of the main types of industrial robots. Their unique design makes them standout from other robot types as they have a spider-like resemblance. In fact, FANUC’s delta robot series is often referred to as the spider robots. Their spider-like design is a result of the parallelogram configuration of their robotic arms. Instead of having just one robust robotic arm, delta robots have three to four lightweight, slender arms. Their arms extend downward from the industrial robot body and connect to a single point. This single point is the tooling plate in which the EOAT is attached. All arms of delta robots work together to control the single EOAT. The motors for the arms are located above instead of within them. This allows for the great agility and speed of delta robots.

Since delta robots are compact with light payloads the applications they can automate are limited. However, they are incredibly advantageous for the ones they can automate. Applications that can be automated by delta robots include:

- • Pick and Place - Robotic pick and place is the most common application automated by delta robots. The super fast speed of the FANUC M-1ia is perfect for quickly picking items off a conveyor. Adding a robotic vision system to a delta robot provides it with greater flexibility with its operation. Vision enabled delta robots can track moving parts on a conveyor, place parts in varying locations, or handle varying part orientations.

- • Packaging - Automated packaging is the second most common application for delta robots. Delta robots can quickly place items in boxes without compromising accuracy. This ensures items are securely packaged and quickly for faster shipping. The overhead mounting of delta robots provides greater accessibility for placing items into boxes or containers.

- • Assembly - Delta robots can also automate lightweight assembly applications. The electronics industry has automated assembly applications with the FANUC M-2ia and other delta robots. They are ideal for handling many of the small components of electronic devices. Their speed is also perfect for the high volumes of electronic device manufacturing.

- • Sorting - Automated sorting is another application type that plays into the speed of delta robots. Delta robots integrated with vision can quickly recognize part types and sort similar ones together.

- • Dispensing - Delta robots can also be used to automate dispensing tasks. Since they are mounted overhead they have better access to workpieces in order to dispense materials such as adhesives or sealants. Delta robots can quickly and accurately dispense materials while parts move along a conveyor.

When to Automate with a Delta Robot

If you are looking to automate one of the applications listed above, you may be wondering if a delta robot will be right for your productions. While having a compatible application is important, there are other factors that also determine if a delta robot will be a good fit, these include:- • Light Payload - The workpieces and tooling will need to be light. Delta robot payloads are typically 12 kg or less.

- • High Speed - The speed of delta robots is their biggest advantage, so you will want to be able to capitalize on it with a high-speed application.

- • Overhead Mounting - Delta robots can only operate overhead so you will need to be sure your production line and application will allow for such operation.