Cobots are unique from other types of industrial robots in that they do not require any safety barriers. Collaborative robots are designed with safety features and sensors for barrier-free operation. This allows them to operate directly alongside and assist humans. Collaborative robots are being used to automate a variety of applications include assembly.

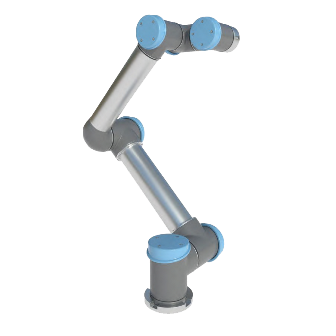

Assembly applications are commonly automated by robots due to the repetitive and precise nature of these processes. Now the Universal UR5 along with other collaborative robots are assisting workers with assemblies that were not possible for automation with traditional robots due to complexity, batch size, or cost issues.

How Cobots Automate Assemblies

Cobots can be used to assist workers with handling intricate or small parts, fastening, inserting, or drilling parts together, or by fetching assembly components. Some assemblies require parts too small for human handling as is the case with electronic devices. The light payload and small size of the Universal UR3e makes it ideal for handling small parts without damaging them. Other assemblies may involve workers preparing/organizing parts while the UR3e then fastens or joins the parts together. Collaborative robots can also be used to retrieve components needed for an assembly, freeing workers to focus solely on the assembly process.Automating Small Batch and High Change Over Assemblies

Prior to the development of cobots, small batch and high change over assemblies were not ideal for traditional industrial robots as the cost and programming time could not be justified. However, hand guided programming makes the automation of these types of assemblies possible with cobots. Anyone can program the FANUC CR-7ia and other collaborative robots with their intuitive programing. Workers can manually guide the robotic arm through the waypoints of an assembly process. The cobot is programmed quickly which is ideal for small batch or high change over assemblies.Cobot Size and Light Mass is Ideal for Assembly

The small size and light mass of collaborative robots makes them ideal for assembly automation. They can handle small components such as screws or computer chips. Their size allows them to be easily integrated along production lines and they can even be tabletop mounted. They can share the same workspace with workers without interference or collisions even in small or confined factories.Benefits of Using Cobots for Assembly Applications

- • Increased Productivity - Adding collaborative robots to assembly lines can increase productivity by up to 85%. Cobots can relieve workers of busy work or repetitive tasks, freeing them to focus on more critical aspects of production.

- • Better Quality - Collaborative robots improve product quality through their accuracy. Robotic force sensors provide sensory feedback to cobots, ensuring precise placement of parts.

- • Conserve Space - Cobots are small robots allowing them to be integrated along assembly lines without taking up much space. Their size not only saves space, but also makes them safer for operating around humans.

- • Adaptable - Intuitive programming allows cobots to quickly adapt to process changes. Users regardless of technical experience can reprogram them through hand guidance.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.