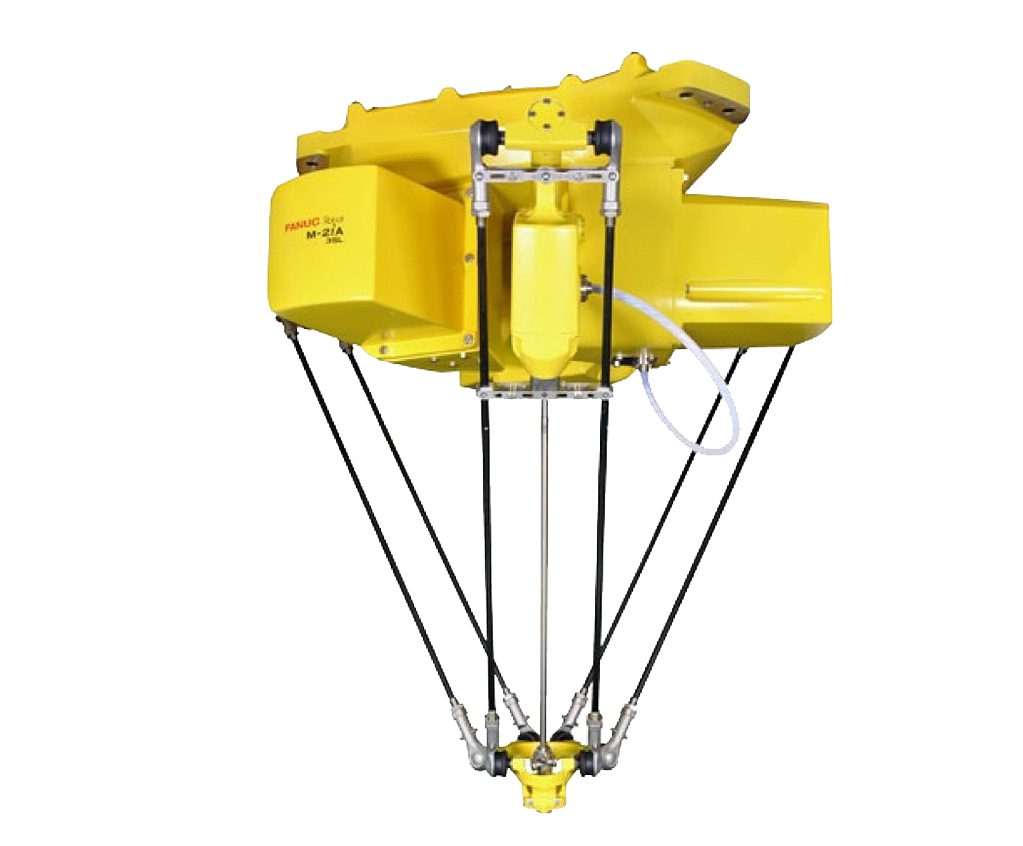

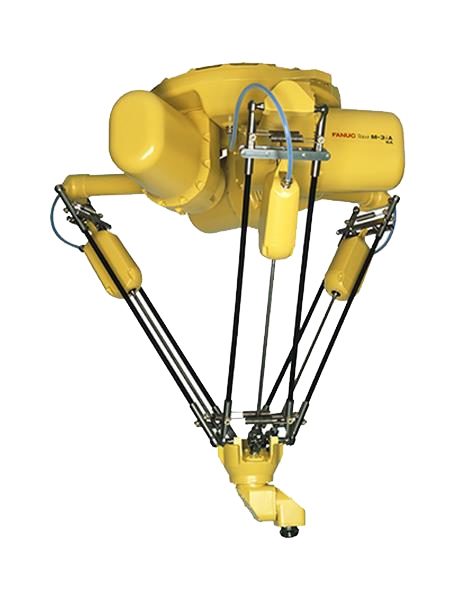

Delta robots are one of the main types of industrial robots. They can also be referred to as spider and parallel robots due to their construction. Delta robots are designed for low payload applications including automated packaging, robotic assembly, and automated pick and place. They are commonly used to serve the food, cosmetic, pharmaceutical, and electronic industries. These factory robots have become quite popular when it comes to automating with industrial robots, especially for assembly processes. The FANUC M-2ia is one of the more common delta robots, helping manufacturers increase productivity while also saving on floorspace. The rapid growth of delta industrial robot arm can be explained by their many advantages with some of the key ones listed below.

Speed

Delta robots are faster than most other types of robot manipulators. In fact, they are 30% faster than SCARA robots. The reason for their incredible operating speeds is because of their design. Other types of industrial robots have a serial-link construction while delta robots have a parallel-link construction. This means their axes are connected mechanically in parallel as opposed to axes joined in a series. The parallel-link design allows for incredibly fast speed, acceleration, and higher cycle duties.

In addition to having their axes connected in parallel, their speed also comes from the weight distribution of their motors. The motors used to control their arms are located in the main robot body as opposed to the industrial robotic arm. This makes all their weight stationary, allowing for extremely light arms. This helps to increase their speed and agility for an obstruction free work envelope.

Selecting the right robotic gripper also plays a key role in the overall operation speed of delta robots. Due to their low payload capacities, delta robots are typically integrated with vacuum end-effectors. These help users to get the most speed from their delta robot.

Productivity

Delta robots allow for much higher productivity rates due to their increased speed and throughput. Delta handling robots can process up to 3 parts per second or 180 parts per minute, significantly increasing throughput. Higher throughput allows for more products to be manufactured. Productivity is also improved with these robotic manipulators since they can turn a 12-hour operation into a 24-hour operation. Delta manufacturing robot arms can run around the clock without stoppages, allowing more products to be produced each day.

Safety

Delta robots are perfect for high speed and high repetition processes, both of which are not ideal for workers. Tasks requiring high repetition and speed can often lead to stress injuries, fatigue, and lack of job satisfaction for workers. Over 30% of work-related injuries are musculoskeletal including muscle strains, carpal tunnel, and rotator cuff injuries. These injuries can lead to increased worker compensation costs and worker shortages for manufacturers. Incorporating a FANUC M-1ia to an assembly line saves workers from injury and improves the overall safety of your manufacturing facility. Workers can transition to less physically taxing jobs, such as operating robots. Delta robots are designed to perform repetitive tasks quickly and consistently without the safety risks.

Footprint

Delta assembly robots take up minimal space compared to other robot types. They have a small footprint and are typically mounted overhead, making them ideal for those with limited manufacturing space. Their small footprint also makes them easy to integrate with a robotic workcell.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.