Material handling is one of the most common types of applications for robotic automation. Automating material handling tasks with industrial robots improves the overall efficiency of a production process. Industrial robots are able to quickly handle parts in a safe and secure manor. One of the reasons material handling is common for robotic automation is because it covers a broad range of tasks including palletizing, depalletizing, part transfer, machine tending, dispensing, and pick and place.

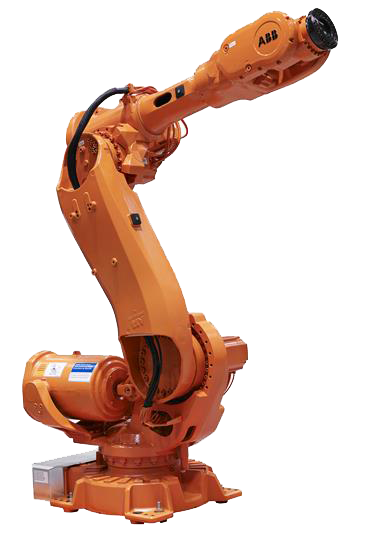

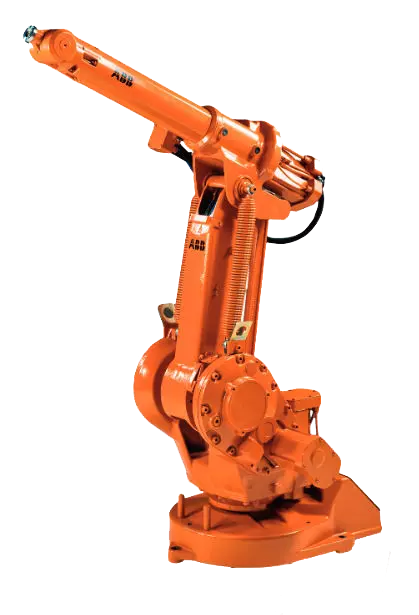

ABB is one of the four major robotic manufacturers in the world. They manufacture a variety of articulated, collaborative, and delta style robots. Many of ABB’s robots make excellent general-purpose robots as they can automate a variety of tasks including material handling. Below is a look at of some of ABB’s best robots for material handling automation.

Light Payload Material Handling Robots

ABB has three lines of articulated robots that can be deployed for light material handling applications. The first is their IRB 100 series which features their light payload, compact industrial robots. Payload capacities in this series range from 3 kg to 6 kg and reaches vary from 580 mm and 810 mm. This series features the ABB 120 which is ABB’s smallest material handling robot. Although the 120 is small, what it lacks in size it makes up for in versatility as it can automate several material handling tasks including robotic assembly, part transfer, and palletizing. ABB’s IRB 100 series fills the void of a lack of small material handling robots in the robotic industry.ABB’s IRB 1000 series also features low payload material handling robots. Payloads in this series start at 5 kg with the ABB 1600 an go up to 10 kg. Six axis robots in this series feature longer reaches than the IRB 100 robots, making them ideal for lighter material handling processes that require more work area.

The last of the lower payload ABB material handling robots are those from their IRB 2000 series. This series covers payloads from 7 kg up to 20 kg and reaches between 1500 mm and 1850 mm. The ABB 2400 is one of the best robots from the IRB 2000 line for material handling automation.