Whats Inside of a Robotic Weld Cell?

There are many components that go into a robotic welding package. Below is an overview of what users can expect inside a typical weld cell.

- • Workcell - The robotic workcell itself is made up of metal barriers in order to enclose the robotic welding system. The workcell barriers effectively block the arc glare and other welding hazards from endangering workers on the production floor. Robotic workcells provide industrial robots with a safe space to weld, allowing them to operate at their full speed. Workcells will include safeguarding features such as area scanners, light curtains, door locks, E-stop, and arc glare shields. Robotic weld cells not only improve safety but also the efficiency and productivity of a welding system.

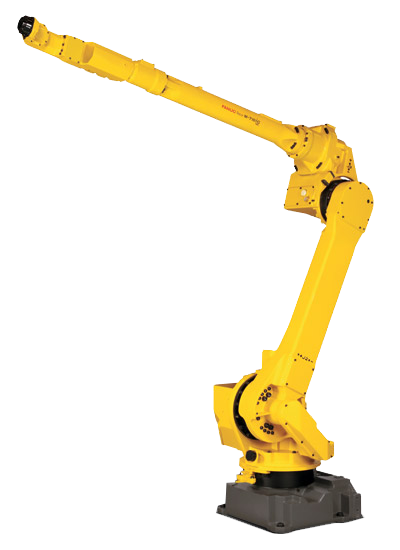

- • Robot - The most obvious component of a robotic weld cell is the welding robot. Robot weld cells may contain one or multiple welding robots within the workcell. The type of robot will depend upon the type of welding application and the workcell itself. For instance, if you are automating an MIG application then a FANUC Arcmate 120ic could be integrated with your workcell. If you purchase a turnkey system, then the robot will most likely be pre-determined by the manufacturer. Dual arm robots are very common in robotic welding cells as they allow it to complete multiple welds at one time and greatly extend the work envelope. Six axis robots are the most common type robot used in automated welding cells. Along with the welding robot will be the controller and teach pendant. These devices are used to program and process the motions and welding applications of the robot.

- • Power Source - In order for an articulated robot to be able to weld metals together it needs to have a source of power. A robotic welding power source provides the electric current needed to generate enough heat in order to melt workpieces to join them together through welding. Popular power sources include the Lincoln Powerwave 455M and the Miller Auto Axcess 450. The Lincolm Powerwave i400 pairs well with used FANUC welding robots like the FANUC Arcmate 100ic for arc welding applications.

- • Welding Torch - The welding torch is the tooling that is connected to the robot wrist and interacts directly with the workpieces. Torches vary based upon the exact welding application that is being completed. There are also different mounting options for the torch to consider. Through-arm mounting has become more common over the years, especially since many welding robots are designed with hollow wrists to accommodate torch wiring. While over-arm mounting was the original standard.

- • Robotic Reamer - A robotic reamer, also known as a torch cleaning station, is a mechanical torch cleaning device. Reamers are typically considered as an option for weld cells, but they are a good investment as they can extend the life of the welding torch and its consumables. Reamers are placed close to the welding robot inside the workcell in order to automatically clean torches of spatter at pre-determined intervals.

- • Positioner - Robotic positioners are used to secure and rotate parts during the welding process. There are several different types of robotic positioners that can be integrated with weld cells. The type of positioner used will depend upon the welding application, robot, part, and amount of rotation needed. For pre-engineered workcells, turntable positioners are the most common. Turntable positioners allow for the quick changing of parts as a robot can weld a part on one side of the table while an operator loads the next part on the other side. The table will rotate in-between welds to change parts.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.