SCARA Robots vs Delta Robots

SCARA and delta robots are both types of industrial robots used in manufacturing. Both types are often deployed for automating high speed material handling applications such as pick and place, assembly, packaging, and part transfer. Both feature high inertias and compact designs. Deciding which type is best for your application can be confusing given both are known for fast material handling. Understanding their differences will help clarify this dilemma and allow you to select the best option for your operation.Architecture

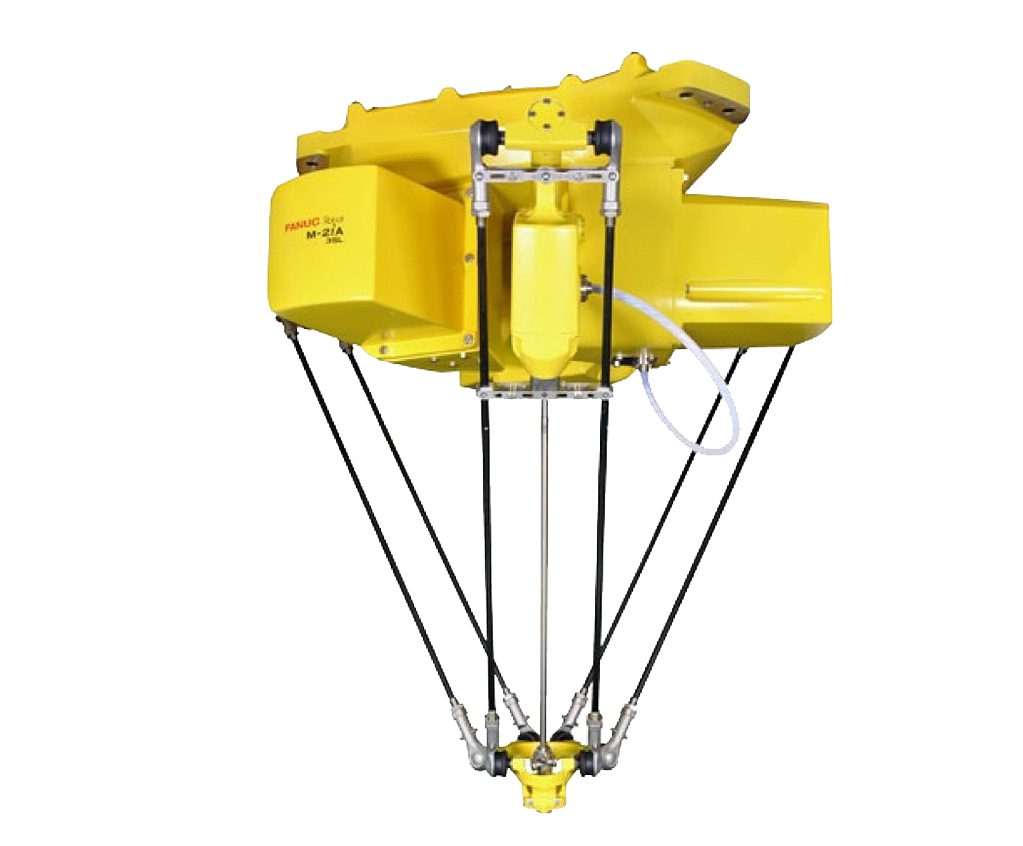

SCARA robots, which stands for Selective Compliance Articulated Robot Arm, feature a structure similar to that of an articulated robot. SCARA’s feature a compact footprint with a robotic base attached to a two link robotic arm. SCARA’s originally were used exclusively for automated assembly which is why their named used to mean assembly instead of articulated. When they began automating other applications, articulated replaced assembly in the acronym given their resemblance to articulated robots. The FANUC SR-6ia is a SCARA robot.Delta robots feature a domed robot body with three to four parallel link arms that extend downward and attach to a single point. What is unique about delta robots is their motors are stationary, located in the body as opposed to in their joints. The FANUC M-2ia is a FANUC delta robot which is often referred to as a spider robot due to its architecture.

Payload

Both SCARA and delta robots are light payload robots. However, SCARA robot payloads are more robust. The FANUC SR-20ia has a payload of 20 kg. Most SCARA payloads range between 0.5 kg to 20 kg.Delta robots given their design and light arms have extremely light payloads. The majority of delta robots have payloads of 3 kg or less.

Repeatability

SCARA robots have the best repeatability out of all robot types. Their stationary Z axis mitigates errors resulting in tolerances under 10 microns. Delta robots therefore are not as accurate as SCARA robots.Speed

While SCARA robots are more accurate than delta robots, delta robots are faster than SCARA’s. Both types are considered the fastest industrial robots, but deltas have an advantage. Since the motors are housed in the robot body as opposed to the joints, the FANUC M-1ia along with other delta robots can operate at faster speeds than SCARA robots.Range of Motion

SCARA robots have a more limited range of motion due to their selective compliance. They have full movement on the X and Y planes but movement on the Z plane is fixed. They are best for automating tasks involving motions from one point to another given their limited range of motion.Delta robot arms are flexible in all three X, Y, and Z planes. Many delta robots feature 6 axes, giving them a full range of motion. They are able to handle movements with some variance as opposed to SCARA’s that can only handle straightforward motions.

Mounting

Both types are compact, taking up less space than other industrial robots. When it comes to installation delta robots can only be overhead mounted. SCARA robots on the other hand can be floor, ceiling, or wall mounted giving users more flexibility with installation.Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling a used robot.