The lifting and moving of heavy objects is a common practice of industrial manufacturing. It is also one of the biggest safety hazards workers in manufacturing face. Repetitive lifting of heavy or large parts can cause muscle strains, stress injuries, and fatigue. The risk of dropping heavy items can cause broken bones for workers as well as potentially damage parts. Manual lifting of heavy items is also incredibly slow, which can hinder cycle times. All of these issues are reasons to automate heavy lifting tasks with an ABB robot.

ABB Robots for Heavy Lifting

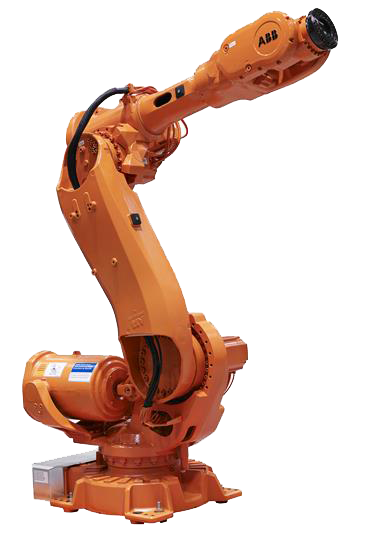

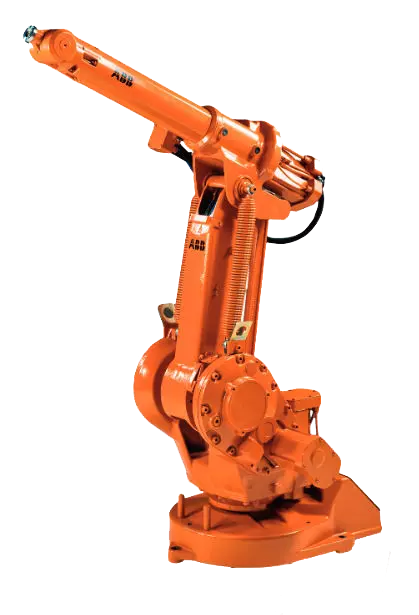

In order to automate a heavy lifting applications, a high payload industrial robot arm will be needed. A industrial robotic arm is considered to have a high payload if it can regularly lift at least 200 kilograms or more. The amount of weight a robotic manipulator can handle is defined by its payload. ABB has several robot manipulator models capable of handling at least 200 kg. Most of ABB’s heavy lifting robots can be found in their 6000, 7000, and 8700 robot series. Industrial robots in the IRB 8700 series feature the highest payloads of any ABB robot with the maximum being 800 kg. The ABB IRB 6640-235/2.55 is one of the heavy lifters from the IRB 6000 series, while the ABB 7600-340/2.8 is a high payload robot from the IRB 7000 series.When considering a high payload factory robot to automate a heavy lifting process it is important to factor in the weight of both the EOAT and workpieces. Robot payload is the total weight the manufacturing robot arm can lift which includes any end-effector integrated to its wrist and workpieces it will need to handle. You want to make sure you do not underestimate your payload as this will hinder the robot’s performance. For instance, if your application will require a maximum weight of 400 kg then the ABB 7600-500/2.55 would be ideal.

Typical Applications for ABB Heavy Lifting Robots

ABB’s heavy lifting handling robots are multipurpose meaning they can automate several different types of applications. These typically include automated spot welding, material handling, palletizing, depalletizing, part transfer, machine loading/unloading, and packaging. Any application that involves working with heavy, large, or bulky parts will be ideal for a high payload ABB robot.Why Automate Heavy Lifting with ABB Robots?

Automating processes that involve heavy lifting will improve the ergonomics of your factory. Workers will no longer have to deal with the repetitive lifting of heavy objects, making their job safer and reducing work related injuries. The ABB IRB 6700-205/2.8 can safely lift and handle heavy objects.Another reason to automate heavy lifting applications with an ABB six axis robot is because of their versatility. While there are other types of equipment that can be used, such as forklifts, they are inflexible. A forklift can only lift and move items. Whereas the ABB 6640 can do that as well as spot weld, depalletize, and assemble parts. ABB articulated robots can be deployed for multiple projects. They can also adapt to various part sizes and shapes.

Lastly, automating heavy lifting with an ABB assembly robot will decrease cycle times. ABB robots operate at fast speeds for long periods of time. This allows for greater throughput, increasing productivity.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.