Components of a Robotic Workcell

Robotic workcells optimize manufacturing while also enhancing the functionality of industrial robots. Below is an overview of the main components of a typical robotic workcell.

- • Barriers - The barriers of a robotic workcell define the parameters of the cell as well as enclose the articulated robot and peripheral equipment. Barriers used for workcells may consist of solid metal panels to completely block and protect workers from a robot’s operation or consist of wire mesh fencing. The type of barrier used will depend upon the robotic application and its requirements. Automated welding and robotic material removal applications benefit from workcells with solid paneling as these applications tend to involve UV light, heat, fumes, or debris. One side of the workcell barriers will contain doors to allow operators to enter the cell. There are typically two options for workcell doors, interlocking doors or window doors.

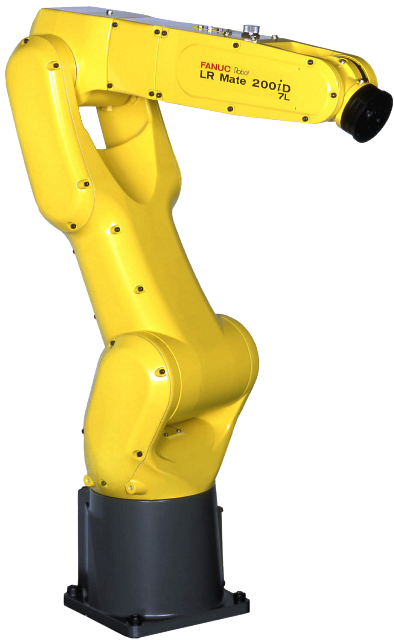

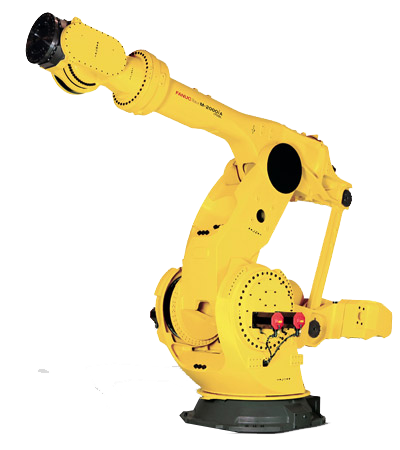

- • Robot - A robot is the main component of any workcell, as it is what performs the desired tasks. Workcells can house one or multiple six axis robots. They may be mounted overhead, on the floor, or on a riser depending upon the exact cell configuration. The type of robot integrated with a workcell will depend on the application being automated. For assembly processes a FANUC M20ia may be selected for the cell. While robotic arc welding would require a FANUC Arcmate 100ic or a similar model. When selecting a robot for your workcell, it is important to take into consideration the robot’s work envelope, payload capacity and reach to ensure it will be able to operate to its full capacity.

- • Safety Equipment - There are many safety equipment options for robotic workcells. Safety equipment is necessary to ensure the proper operation of a robot as well as to protect the operator or any other floor workers. Many pre-engineered workcells come standard with a safety package of pre-selected devices and sensors. Safety light curtains and area scanners are both types of invisible barriers. They emit infrared light in an open area of a workcell, when their light field is broken, they signal the robot to stop. For weld cells, arc glare shields and dividers are used to protect operators from arc glare and weld spray.

- • Peripheral Equipment - Peripheral equipment included with a workcell will consist of items such as the robot end-effector. For workcells designed for material removal, a ABB IRB 4600 may be integrated with a cutting device for its EOAT. While a Motoman MA1400 will need a welding torch for robotic MIG applications. Factory robots may be integrated with vision systems for more precise operation inside the cell or for automating more complex tasks. Weld cells will include peripherals such as a power source, wire feeder, reamer, and positioner.When automating with industrial robots it is very important to understand which peripheral equipment is needed up front. Many used FANUC robots for sale include integration equipment from the previous application.

- • Operator Station - All robotic workcells are equipped with an operator station, also referred to as an ops station. An ops station is an external control panel that is located on one of the cell barriers. This control panel controls the operation of the entire workcell and will consist of six to nine buttons. Standard operator station buttons include e-stop, reset, hold, cycle start, and servo on. Specific configurations and buttons will vary by manufacturer. Operator stations provide a user-friendly interface to simplify the operation of robotic workcells.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.