Components of Robotic Vision Systems

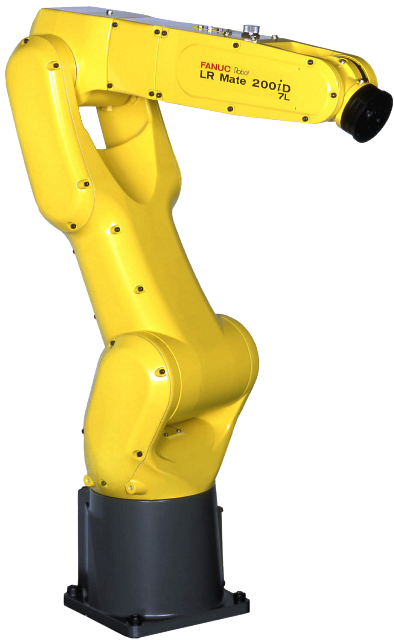

Today’s industrial robots are expanding manufacturing capabilities by being able to complete more complex and detailed applications than their predecessors. One of the drivers behind the advancement of robots is the use of robotic vision systems. Robot vision systems can be integrated with almost any industrial robot to provide enhanced guidance for increased accuracy and efficiency. Integrating vision with a FANUC LR Mate 200id provides additional intelligence needed for it to operate autonomously and make on-demand decisions about its operation. There are many types of robotic vision systems, but all feature the same main components. Below is a breakdown of those components and how they function to provide intelligence to robots.

Lighting

Proper lighting is vital to the success of robotic vision systems. Poor lighting can cause an image to be undetectable to a robot resulting in an inefficient operation and loss of information. Images are formed when light reflected from an object is analyzed. Lighting can improve image quality by illuminating parts so their details standout. This is especially important for advanced applications such as inspection and intricate assemblies where detecting details is critical. Proper lighting can allow a ABB IRB 120 to recognize the small holes of a part for inserting pins during an assembly process.Lenses

The lens of a vision system directs the light in order to capture an image. Lenses can directly affect image resolution and quality, so it is important to ensure your vision system is using a lens best suited for your application requirements. Vision systems typically consist of two lens types. These are fixed lenses and interchangeable lenses. Fixed lenses use autofocus and can be adjusted mechanically. Distances are predetermined for fixed view fields. Interchangeable lenses are composed of a combination of CS-mounts and C-mounts.Image Sensor

Image sensors are responsible for converting the light that is captured by the lens into a digital image for the robot to later analyze. Image sensors delicately balance noise, sensitivity, and dynamic range to create a high-quality image. They can also determine the resolution of an image. An image’s resolution is important for robotic applications as higher resolutions allow for more detail and accurate measurements of objects.Vision Processing

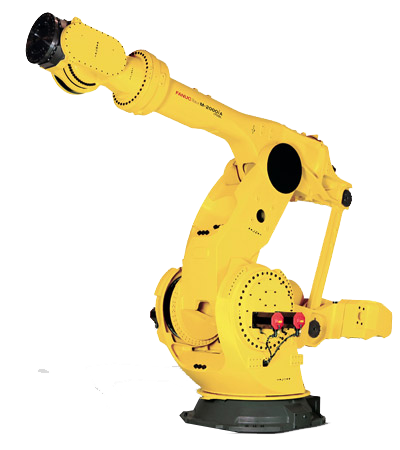

Vision processing is how robotic vision systems obtain data from an image that is used by robots for analysis in order to determine their best course of action for operation. Vision processors are one of the key components of any robotic vision system since they convert images into valuable information for robots to evaluate. Vision processing typically requires several steps before a decision can be finalized. For instance, vision processing converts an image of a part being inspected by a FANUC M20ia into data that is then analyzed to determine if a flaw is detected on the part. This information is communicated to the M-20ia in order for it to determine if the part can proceed with manufacturing or needs to be pulled from production.Communications

Communications connect and coordinate all robotic vision components. This allows all vision components to effectively and quickly interact and communicate for a successful system. Communications for robot vision may involve discrete I/O signals, serial connections, or Ethernet/IP.Robotic vision systems are a key component to consider when automating with industrial robots. Proper research should be conducted on when to implement a robotic vision system.