Collaborative robots are still relatively new to manufacturing, yet over the past few years they have consistently been one of the biggest trends. Cobots are easier to install, program, and operate than traditional industrial robots. They also provide quick changeovers and require significantly less equipment than other robotic systems. All of these factors make collaborative automation appealing to both novice and experienced robot users.

FANUC and Universal both manufacture some of the most popular collaborative robots. Below is a comparison of how FANUC’s new CRX cobots stack up to Universal’s UR collaborative robots.

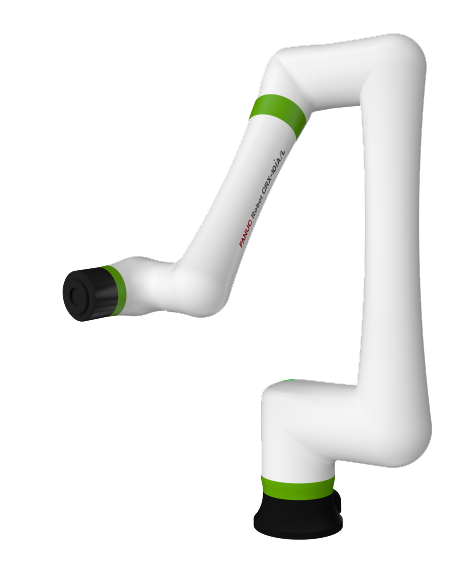

FANUC CRX Cobots

FANUC originally entered the collaborative robot market in 2015 with the release of their CR series. While FANUC is known for their powerful traditional industrial robot arms, they have also found success with cobots. So much so that they have recently released a new generation of collaborative robots with their CRX series. The CRX series features five collaborative robots, including the CRX-10ia and the CRX-25ia. The CRX robot manipulators feature slim frames, a light mass, and a compact footprint. Payloads range from 5 kg and go up to 25 kg. Reaches for the series start at 994 mm and go to 1,889 mm. The CRX cobots feature a white epoxy coating which makes them rust and chemical resistant and ideal for settings with stringent cleanliness standards.Safety features of the CRX series include rounded exteriors and built-in sensors for people and object detection. When either are sensed the cobot will immediately stop operating to prevent accidents. The CRX cobots also feature hand guidance programming along with FANUC’s new drag and drop tablet interface. Users of the FANUC CRX-10ia/L and the other CRX cobots have two intuitive programming options. The CRX cobots are also designed with 8 year zero maintenance on motors, reduces, sensors, cables, and grease.

The CRX cobots can automate a variety of applications including robotic welding, inspection, machine tending, material handling, and material removal.

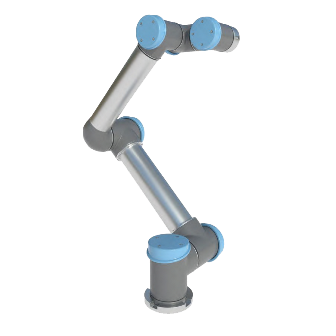

Universal UR Cobots

Universal exclusively manufacturers collaborative robots. Universal launched its first collaborative robot series, the UR series, in 2008. It featured the Universal UR5 and the UR10. Since then it has updated its cobot line to the URe series. Universal’s URe series is its second generation of collaborative robots and includes the Universal UR16e. Universal cobots feature payload capacities of 3 kg to 20 kg. While reaches start at 550 mm and go up to 1,750 mm. Those needing a cobot with a longer reach or higher payload would want to consider one of the CRX cobots, while those needing a lighter payload or shorter reach could benefit from one of the UR cobots.Like the CRX cobots, the UR cobots feature a light mass and compact footprint. Universal states their cobots are designed for tabletop operation or to be installed inside machinery. They can also operate without barriers due to their light mass and safety sensors. The UR cobots feature hand guidance programming or the option to program with their touchscreen tablet. Universal UR cobots provide incredibly fast installations that take only a few hours due to simple programming and setups. These cobots can automate many of the same applications as FANUC’s CRX cobots including welding, material handling, material removal, and machine tending.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.