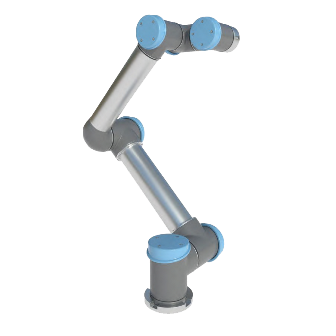

Automation has played a role in manufacturing for quite some time. However, in recent years there has been an acceleration of the adoption of robotic automation. More companies are automating their manufacturing facilities with a range of industrial robots. The acceleration of robotic automation has led to the growth of collaborative robots. Cobots are a cost-effective, safe, and intuitive alternative to traditional robot manipulators. The Universal UR5 and other cobots are commonly used to automate material handling applications. Assembly processes in particular have become popular for cobot automation and for good reason as there are many benefits to a collaborative robot assembly line.

Compact Size

Collaborative robots are designed with a compact footprint and light mass. This makes them easy to implement along assembly lines. Cobots can fit along dense production lines without the risk of peripherals interfering with their operation. Their small size and light weight also makes them easy to relocate. Collaborative robots also do not require the same safety barriers of traditional industrial robot arms which reduces the total footprint of the robotic system. Less extra equipment along with a small frame means the FANUC CR-15ia will take up minimal space.Low Payload

Most cobots feature a payload of 20 kg or less, with the exception being FANUC’s CR-35iA. The low payload of collaborative robots makes them ideal for handling many of the small or delicate parts that are common with automated assembly applications. Cobots can gently handle and assemble small parts without damaging them.Collaborative Operation

Unlike traditional factory robots that must be closed off and away from humans when operating, cobots are designed to safely work collaboratively with human workers. Their collaborative operation allows them to automate processes that still require some human involvement. It is not just people that cobots can collaborate with, they can also work with other equipment and cobots.Quick Programming

Programming cobots is quick and easy with hand guidance. Moving the arm of the Universal UR10 through the steps of an application allows for programming to take place within minutes. This shortens changeover times, making automating assemblies with a high mix of products possible.Low Startup Cost

The initial cost of investing in a collaborative robot system can be considerably lower than other articulated robots. The elimination of extra safety equipment also keeps the cost of automating with a collaborative robot on the lower end.Adaptable

Collaborative robots are extremely adaptable. Their quick programming allows them to be easily reassigned to fill in where needed. If there is a sudden labor gap in one area of an assembly line, the KUKA lbr iiwa 14 R820 can be quickly reprogrammed to fill in the vacancy. Cobots can also be installed on top of a cart, allowing them to be easily moved around assembly lines.Improve Productivity

Adding a collaborative robot to your assembly line will significantly increase productivity. Cobots can assist workers and take over repetitive tasks of assemblies. This allows for more work to get done, improving productivity.Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.