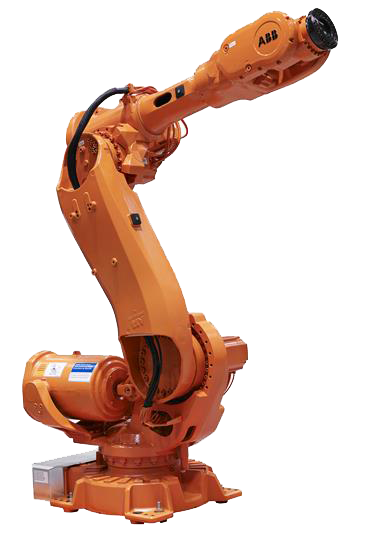

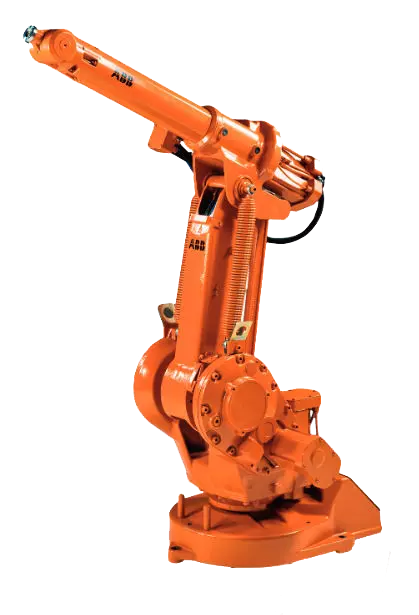

ABB robots are considered to be amongst some of the best in the world. ABB’s factory robots have been used to automate a variety of manufacturing applications across numerous industries. Their accuracy, precision, and durability make them ideal for automating challenging processes such as those that fall under the material removal category.

Material removal processes involve removing excess material from a workpiece. These applications are often required in order to prepare a part for another application or as one of the final steps to finish a workpiece. Material removal applications can be demanding, requiring great skill and concentration. In addition, they can also be some of the dirtiest manufacturing jobs due to debris and particles produced as a result of removing material. Automating material removal applications with ABB six axis robots resolves these issues. ABB industrial robot arms are commonly used to automate cutting, deburring, grinding, and polishing applications.

Cutting

For cutting applications an ABB manufacturing robot arm is integrated with a cutting device for its EOAT. The specific tooling used will depend upon the exact type of cutting application being automated. During a cutting application a workpiece is divided into smaller sections. This is typically done to prepare a workpiece for another application such as welding.

There are several different types of cutting applications. The cutting applications frequently automated by ABB robots include laser, plasma, and oxyfuel cutting. Integrating the ABB 2400L with a plasma torch allows it to automate plasma cutting as well as plasma welding. ABB's IRB 4400/L10 is ideal for performing oxyfuel cutting applications.

Deburring

Deburring is a type of material removal process used to finish workpieces. During a deburring process an ABB articulated robot will use specialized tooling to remove any imperfections or inconsistencies from parts such as burrs, fins, or uneven edges. Deburring is often required after die casting or injection molding processes. The ABB 4600/40 is ideal for automating deburring. The precision of the ABB 4600/40 ensures accurate deburring, preventing too much material from being removed. Defects are eliminated from each part, improving the overall quality of the finished product.

Grinding

The ABB 4600/20 and 2600-20 are two examples of ABB industrial robots that can be used to automate grinding applications. Grinding is another material removal process used for finishing products. For automation, an ABB robot is integrated with an end-effector that contains some type of abrasive in order to grind away material to produce a smooth and even surface on the part. Automating grinding applications improves the quality and consistency of parts. Grinding is also one of the more hazardous jobs in manufacturing, so automating with an ABB industrial robotic arm will lead to a safer work environment for employees.

Polishing

Polishing is the last type of material removal process that is often automated with ABB robotic manipulators. ABB's IRB 2400 is ideal for automating polishing processes. Like deburring and grinding, polishing is a type of material removal application used for finishing. During polishing an ABB robot manipulator will apply an abrasive to a workpiece in order to smooth and shine its surface. Automating with an ABB robot will ensure an even finish that is uniform from part to part.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.