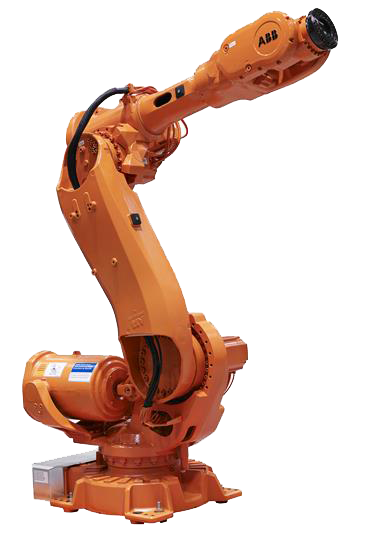

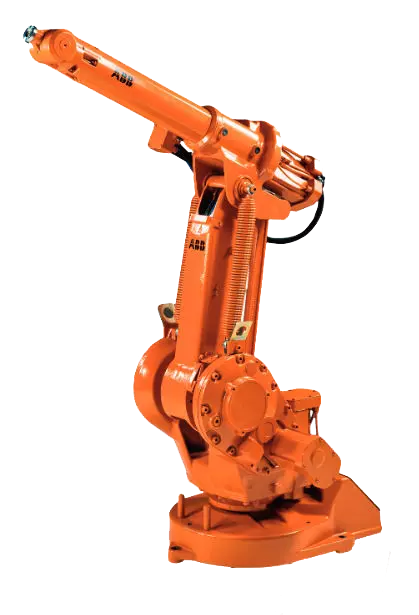

ABB is one of the top robotic companies in the world. Their industrial robots have been automating production floors for decades. They manufacture a variety of multipurpose robots ranging from small to large that are capable of automating numerous applications including welding, assembly, material handling, material removal, and palletizing. It is not just their new robots that are popular, but their used ones as well. Used ABB robots, like the ABB IRB 2600-20, have been implemented by the automotive, food, energy, metal, and oil and gas industries along with several others. Why are so many industries automating with used ABB factory robots? The top reasons are listed below.

Less Expensive

The number one reason companies are automating with used ABB robotic manipulators is because they are less expensive than new ones. Many companies do not have unlimited capital and with increasing costs it can be difficult to find the budget to afford to automate. However, with used ABB robots, robotic automation is significantly more affordable. The average used industrial robot arm cost can be between 40% to 60% less than the cost of a new robot. Buying a used ABB 6640 is much more cost-effective for any size budget. It is not just the initial cost that is more affordable, but also the maintenance of the robot manipulator. Used robots will be compatible with used parts. When components of a used articulated robot begin to wear or need to be replaced, second-hand parts can be used, reducing repair costs.Better Availability

One issue that has become apparent in the past few years is the lack of availability and long delivery times for new industrial robotic arms. Some new robots can take several months to be delivered. Long delivery times are not ideal for those wanting to improve their productions with robotic automation and impractical for those needing to replace a broken down handling robot. Used ABB robots are readily available and can be shipped quickly. Lead and delivery times are significantly shorter allowing companies to automate in less time with a used ABB 1600 than a brand new robot.Can be Integrated with Used Robotic Equipment

Another reason to consider buying a used ABB manufacturing robot arm is because of its compatibility with other used robotic equipment. Those replacing a robot in a pre-existing robotic system can find a similar robot or the exact same robot by buying used. This preserves the rest of your robotic equipment and avoids replacing the entire system as a new six axis robot may not be compatible. For those buying an entire robotic system, buying a used ABB 4400-L10 allows for you to purchase other used equipment, reducing the total cost of the system.Same Benefits as a New Robot

One of the biggest misconceptions about used robots is they will not be as beneficial as a new robot with the latest technology. This simply is not true as a used ABB robot provides many of the same benefits as a new robot. Automating with a used ABB robot will reduce production costs, increase productivity, improve quality, reduce ergonomic issues, and overall will create more efficient manufacturing.Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.