One of the most popular technology options for industrial robots is robotic vision systems. Vision systems enhance the performance of industrial robots for a complete optimized operation. Robots integrated with vision are more accurate, intelligent, and autonomous. Many robot manufacturers have developed their own in-house vision systems for easier integration with their robots. ABB is one of those manufacturers, offering four different vision options to cover a wide range of robotic applications.

- • Integrated Vision - ABB’s integrated vision system can be deployed for guidance, inspection, and the tracing of workpieces. It features over fifty smart vision tools that simplify the integration of a robotic system, allowing for quick deployment. Adding Integrated Vision to the ABB 1200 allows it to thoroughly inspect parts for enhanced quality control. Integrated Vision cameras are enclosed in a compact IP67 rated case, ensuring the vision system can withstand even harsh conditions. Even in dusty, humid work environments, ABB’s Integrated Vision provides reliable feedback to the 1200. Other features of this vision system include faster optics and image capturing, the ability to control external lighting, and predefined program options.

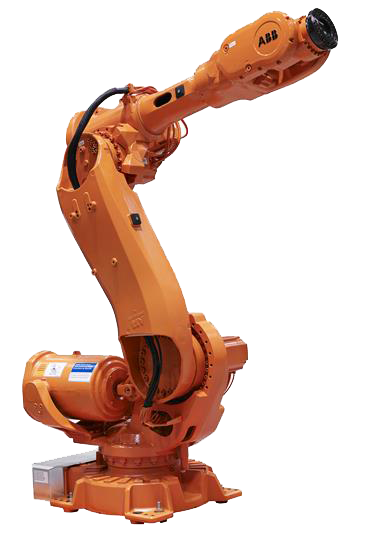

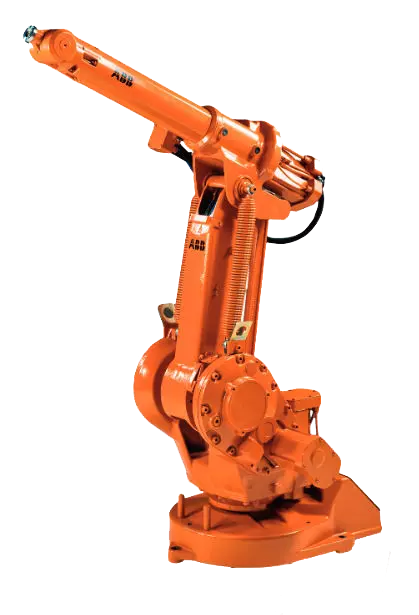

- • FlexLoader Vision - ABB’s FlexLoader Vision system is designed for guiding ABB robots through automated material handling and machine tending applications. Integrating the ABB 4600-40/2.55 with FlexLoader Vision allows it to be able to identify different part locations. This vision system can recognize parts with complex geometries and various sizes without the need for additional fixtures. In addition, articulated robots are able to learn new workpieces with this vision system in less than ten minutes resulting in significantly less downtime for process changes. This vision system can produce either 2D or 3D images. Other features include collision avoidance, PC architecture, user defined grippers, and moving/rolling part avoidance.

- • PickMaster Twin - PickMaster Twin is ABB’s highly sophisticated vision system for automated pick and place and packaging applications. This vision system allows for extremely accurate picking and packaging in highly randomized applications. Using PickMaster vision the ABB 2400L is able to identify and pick random parts arranged in no particular pattern. This vision system supports circular conveyor tracking for complex picking applications. PickMaster is compatible with all ABB robots operating with the IRC5 controller. It can be installed in a single robot workcell or along production lines with up to ten six axis robots. With PickMaster vision output will be maximized with faster cycle times allowing for greater productivity.

- • 3D Quality Inspection - ABB’s 3D Quality Inspection, also referred to as 3DQI, is their vision system specifically designed for inspection applications. This system uses 3D technology to scan products for defects for greater quality control. This system is able to detect defects that would otherwise be impossible to see with the human eye. Defects as small as half the width of a human hair can be detected with the 3DQI vision system. Not only can this system detect microscopic faults, but it can do so significantly faster than other inspection systems. 3DQI will increase product quality through precise inspections while also reducing rework and material waste. ABB robots with 3DQI vision have been used by manufacturers in the automotive, aerospace, and transportation industries for performing quality inspections.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.