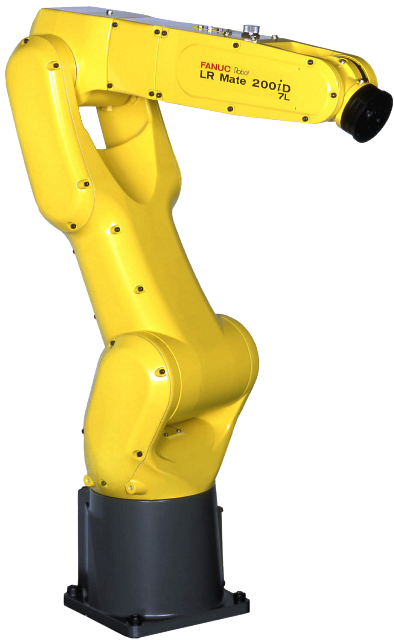

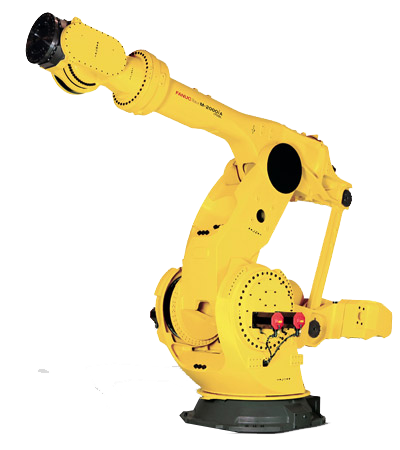

The use of robotic automation is growing rapidly each year. Companies are evaluating their operations to see where they can benefit from implementing industrial robots. One of the manufacturing processes that is becoming more automated is screwdriving. The Universal UR5 and FANUC LR Mate 200ic are two industrial robot arms capable of automating screwdriving. The growth of robotic screwdriving is attributed to its many advantages which include:

- • Higher Productivity - Automating screwdriving with the ABB IRB 140 and other assembly robots increases productivity. Articulated robots can take on greater workloads than humans which increases throughput. The greater the throughput the higher productivity rates will be. Higher productivity allows companies to keep up with and meet consumer demand.

- • Better Product Quality - Automating screwdriving will also improve product quality. Robot manipulators are accurate and precise. They are programmed to follow application paths without any deviation. This ensures screws are accurately placed and securely fastened. Product quality is important for any item but for some it can have critical safety implications. Better product quality will reduce safety issues and lead to less product recalls.

- • Faster Cycle Times - Cycle times will improve with robotic screwdriving. Six axis robots work at much faster speeds than humans. They also do not take breaks or get distracted. Their accuracy prevents errors which decreases the likelihood of rework. With articulated robots screws are quickly and correctly fastened the first time, significantly reducing cycle times.

- • Reduces Downtime - Downtime can be significantly reduced with robotic screwdriving. Unlike workers, industrial robotic arms do not need breaks, sick days, or vacation. Their operation is also not limited to a certain number of hours. In fact, factory robots can operate around the clock. When products change, assembly robots can be quickly reprogrammed. There is no need to take time for retraining employees. Less downtime means your operations will be more productive.

- • Consistent Labor - Manufacturing robot arms also bring consistency and reliability to your screwdriving applications. robotic manipulator excel at repetitive tasks such as fastening screws into objects. They are programmed to move from part to part. Workers may become distracted or tired, causing inconsistent or slow labor. When companies rely on manual labor they are also prone to turnover issues which can hinder manufacturing. Industrial robots provide a reliable screwdriving solution.

- • Lower Costs - Production costs can be lowered by automating screwdriving with the Yaskawa Motoman MH5 or another industrial robot. Using robotic automation means there are fewer salaries to pay, lowering labor costs. Higher product quality means fewer errors and waste, reducing material costs. Better quality also reduces the likelihood of costly product recalls.

- • Adaptable - Another advantage of screwdriving robots is they are highly adaptable. Handling robots can adapt to product, process, or volume changes. They can also automate other applications besides screwdriving. This gives companies greater flexibility with their manufacturing. As companies grow and change, industrial robots can adapt to meet new demands.

- • Fewer Workplace Injuries - The repetitive nature of screwdriving can cause stress injuries to workers. Operating tooling can also be hazardous for workers. Automating screwdriving with robots removes workers from any harm. The work environment becomes safer while reducing the worker injury claims paid out by employers.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.