How FANUC Robots are Improving the Electronics Industry

Today’s technology driven world has caused rapid growth within the electronics industry. High production demands, constantly evolving products, and fierce competition has led electronic manufacturers to automate their operations with FANUC robotics. FANUC robots are known for their reliability and efficiency, which is why they are a perfect fit in the electronics world. Manufacturers are needing to turn out products at faster rates while not sacrificing on quality. FANUC helps them accomplish this and even helps to increase quality while also decreasing costs.

Electronics is one of the most innovative industries with products that are constantly changing and devices that are becoming smaller in size with every new product line. These shrinking products require smaller parts for manufacturing, so small that they are becoming too delicate for human handling. FANUC robots meet this challenge and are able to handle the smallest of parts with increased speed and the upmost precision.

Keeping Electronics Clean

It may be surprising to learn the manufacturing of some electronic devices require the same cleanroom standards as those found in the food or pharmaceutical industries. Parts for these devices are sensitive to particles such as dust, liquids, and gases. Their integrity can become compromised if they come into contact with any of these substances. This is where FANUC cleanroom robots like the FANUC M20ib/25C come into play. FANUC cleanroom robots meet the stringent requirements for the clean production of electronics. They contain special coatings and non-gassing lubricants to prevent shedding of particles onto parts while in operation. Electronic devices are built to the highest quality standards consistently with the high repeatability of FANUC’s robots. The elimination of human handling prevents contamination and the risk of defective products.Applications

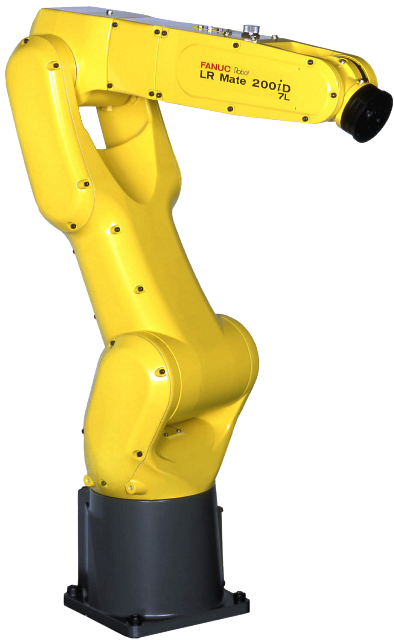

FANUC robots can automate a number of applications to improve the manufacturing of electronics. Some of the most common ones include:- Assembly - FANUC robots, such as the FANUC LR Mate 200ic, are integrated with vision and force control software allowing them to be able to accurately and carefully assemble electronic parts like computer keyboards. These software systems also provide them with the capability to dynamically locate and place parts in the smallest and tightest of spaces. Grippers are designed for precision and to handle higher speeds to prevent any bending, breaking, or cracking of delicate parts.

- Inspection - Vision systems are also useful for enabling FANUC robots to complete inspection of devices, even while they are assembling components. Defects and errors are caught before production is complete helping to turn out high quality products consistently.

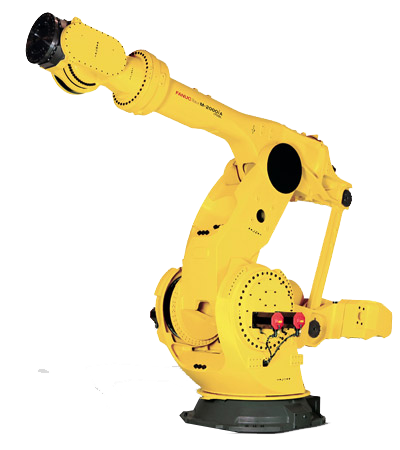

- Dispensing - Electronic components such as screens and covers are often secured though the use of adhesives. FANUC dispensing robots like the FANUC M-20ia accurately disperse beads of adhesives to ensure components are attached securely. Dispensing robots are also used to apply sealants to electronic parts to protect them from any atmospheric contaminants.

- Packing - Packing is often one of the last applications of a manufacturing process and needs to be completed with precision, especially with electronics to prevent damage before and during shipping. FANUC packing robots, such as the FANUC M-420ia, are capable of carefully packing individual products into boxes and then placing them into larger cartons. These cartons are then palletized and ready to be shipped out.