FANUC Robotics in the Oil & Gas Industry

While industrial robots have been around for decades in many industries, the oil and gas industry is new to welcoming them to their operations. For many years the high cost of oil brought soaring profit lines to these manufacturers, so much so that inefficiencies in the industry were masked. However, that began to change a few years ago when the cost of oil began to significantly drop along with their profit margins. The lowering of oil prices and high production costs has led to the oil and gas industry to adopt robotic automation in order to increase efficiency. FANUC is one of the robotic manufacturers entering into this field and is helping oil producers with the automation of their machining equipment processes. FANUC robots are helping to increase productivity, reduce cycle times, and lower costs; allowing these manufacturers to return to healthy profit margins.

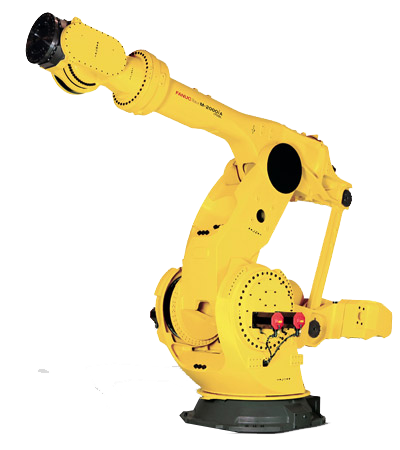

Equipment used by oil and gas manufacturers often needs to be manufactured before it is moved out to the field, either on land or at sea. These workpieces include parts for large pipes that are used to collect and transfer oil to off-shore wind turbines as manufacturers begin to explore alternate methods of energy sources. FANUC offers a well-rounded line of robots that are often used for arc welding, assembly, dispensing/sealing, machine tending, material removal, and part transfer applications during the manufacturing of these systems. The incredible precision provided by the use of FANUC robots, ensures these systems are durable enough to withstand the harsh environmental conditions of oil fields and rigs.

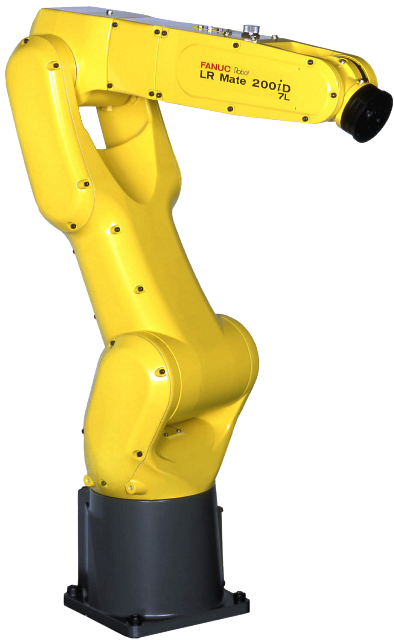

Parts needed to manufacture oil equipment are typically composed of tough to cut materials and tend to be quite large in size. The size and toughness of these parts make them a challenge for humans to work with and pose a safety risk. FANUC offers a variety of robots from the high payload FANUC R-2000ib/210F to the long reach FANUC M-710ic/12L. These robots are capable of handling large and heavy workpieces with ease and greater speed to reduce cycle times.

Their accuracy further reduces cycle time by ensuring applications are executed correctly and eliminating the need to go back to correct any errors. Costs are lowered as the waste of expensive materials are eliminated. For example, FANUC’s FANUC M-710ic/20L is used by oil manufacturers to weld together large pipes that will later be placed out in the field or oil rig. Its precision ensures the welds of the pipe are durable and weaknesses in the pipe will not occur during operation. The durability of the pipes is important as this can help to prevent oil spills and protect worker safety. FANUC welding robots provide high repeatability so oil producers can be confident all equipment meets the same high quality.

Plasma cutting is another process that has recently become automated in the manufacturing of oil equipment with robots like the FANUC Arcmate 120ic. Integrated with touch and laser sensing the robot can cut precise measurements of pipe while the pipe moves along an infeed conveyor. Constant Path software keeps the robot on the correct path without any deviation, providing greater accuracy than its human counterpart.