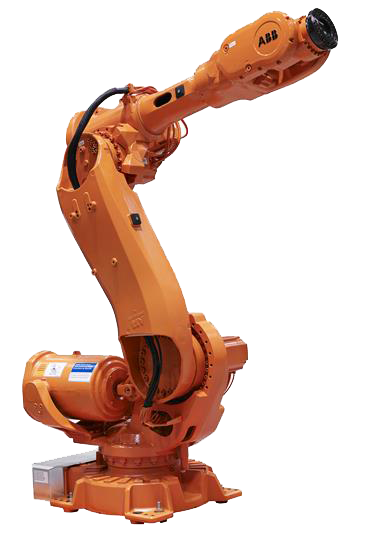

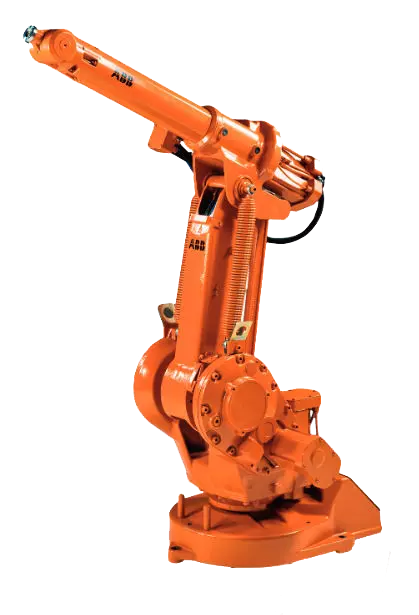

Electronic devices have become fundamental to our daily lives. The electronics you use routinely were most likely manufactured by an industrial robot and perhaps even with an ABB robot. ABB robots have been serving the electronics industry for over a decade. Their material handling, material removal, and assembly robots have automated many production lines in the industry. Chances are high that if you were to observe an electronic assembly you would see a ABB IRB 120 or a ABB IRB 1600 on the production floor.

High product demands, ever evolving technology, shrinking part sizes, and sensitive components are some of the issues today’s electronic manufacturers commonly face. Implementing ABB robots provides a cost-effective solution for these issues. Their robots operate at fast speeds and are capable of running twenty-four hours a day. This significantly reduces cycle times and boosts productivity to meet increasing consumer demands.

ABB robots provide a flexible automation solution which is beneficial to electronic manufacturers since many product lines have short lifespans due to constant advancements in technology and short consumer attention spans. The ABB IRB 2600-12 is capable of covering multiple applications including assembly, pick and place, and packaging. If the smart phone line it was being used to assemble were to become discontinued the company is not at a loss with the robot. The ABB 140 can be reprogrammed and redeployed for the assembly of a new product line or moved to another robotic application such as packaging devices for shipment. With ABB robots, manufacturers are able to easily adapt to changing electronic trends without having to completely overhaul a production floor.

The vast majority of today’s electronics are composed of delicate, tiny, and sensitive parts. As devices become smaller and smaller so do their components. Many of these parts are too small or delicate for human handling. ABB’s robots are able to meet this challenge with their precision and accuracy. The controlled movements of the ABB 1410 provides the ability to insert parts with exact tolerances without jamming during assembly applications. This prevents parts from becoming damaged and speeds up cycle times since products are built correctly the first time. In addition, time is not wasted try to correct errors or figure out how two workpieces should fit together. Integrating ABB robots with vision systems also aids with the assembly of intricate or tiny parts by providing imagery guidance to robots. Robotic vision also allows ABB robots to be utilized for inspection applications with the capability to detect microscopic defects for the upmost quality control.

As mentioned above many electronic parts can be sensitive and may become compromised if they come into contact with liquids, dust, or other particles during manufacturing. Preventing contamination of these parts is extremely difficult with human workers. This is why many manufacturers have implemented cleanroom robots from ABB. These robots are designed to meet stringent cleanliness standards and prevent particle intrusion form occurring during manufacturing since they feature a special coating and lubricant to prevent contamination. Defective products become an issue of the past as quality is significantly increased.

Robots Done Right |

Used Robot Sales |

Improving Electronics Manufacturing with ABB Robots

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.