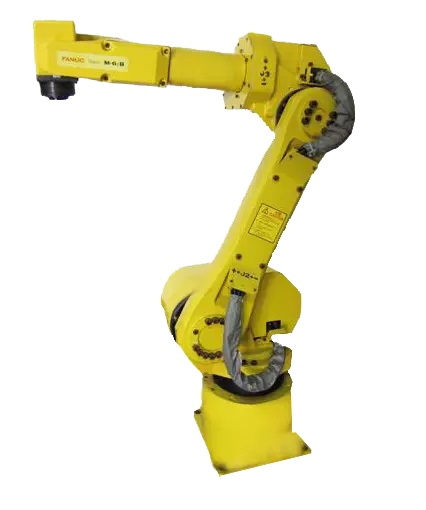

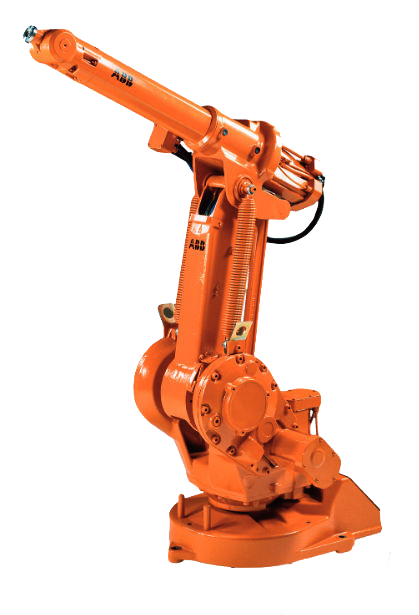

FANUC M-6iB vs ABB IRB 1600

The FANUC M-6iB and the ABB IRB 1600 are two common industrial robots used for a variety of low payload applications. Both FANUC and ABB are amongst the top robotic manufacturers in the world with each of their industrial robot arms being top choices for robotic automation. When two top robotic manufacturers have developed similar robot manipulators like the M-6iB and IRB 1600, deciding which robot to automate with can be difficult. The FANUC M-6iB and ABB IRB 1600 do share some similarities, but they also have some differences that can determine which robot will be the best fit for your application.

- • Payload - Both the FANUC M-6iB and ABB IRB 1600 share the same payload capacity of 6 kg. This means these factory robots can only be integrated with light tooling and can handle lightweight parts. Both the M-6iB and IRB 1600 have multiple variations that feature different payloads. The M-6iB robot variants have a slightly wider payload range of 2 kg, 6 kg, and 10 kg. While the variants of the ABB IRB 1600 feature payloads of 4 kg, 6 kg, and 10 kg.

- • Reach - The standard FANUC M-6iB features a slightly longer reach than the IRB 1600. The M-6iB has a maximum reach of 1,373 mm while the standard IRB 1600 has a maximum reach of 1,200 mm or 1.2 M. Those needing a compact robot with a longer reach may consider the M-6iB. While those with a more confined work area could benefit from the slightly shorter arm of the ABB IRB 1600. The different variations of each robotic manipulator also offer different reaches. The ABB 1600 does come in a 1450 mm variant. The M-6iB robots overall have less of a range in maximum reach than the IRB 1600 robots.

- • Repeatability - The FANUC M-6iB features a repeatability of +/- 0.08 mm. While the ABB IRB 1600 features a repeatability of +/- 0.02 mm. The ABB will be more precise than the FANUC.

- • Applications - The FANUC M-6iB and ABB IRB 1600 can automate many of the same applications. These include material handling, material removal, assembly, machine tending, dispensing, and packaging. In addition to these applications, the FANUC M-6iB may also automate cleanroom and testing processes. The ABB IRB 1600 may also be used for spraying and welding automation applications.

- • Installation Options - Both articulated robots allow for multiple installation options, making them easy to integrate on production floors. Both robots can be floor, wall, overhead, and angle mounted. The IRB 1600 also features two additional installation options allowing for shelf mounting or to be installed inside machinery.

- • Speed - Overall the ABB IRB 1600 features faster axis speeds than the FANUC M-6iB, making it the faster manufacturing robot arm out of the two. The ABB IRB 1600 is designed to be one of the faster low payload robots with cycle times averaging up to 50% shorter than other robots in its class for automated material handling and machine tending. Those needing a high speed material handling robot would benefit from the ABB IRB 1600. While the FANUC M-6iB may not be as fast as the IRB 1600, it will still speed up production times.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling a used robot.