Collaborative robots have become one of the biggest trends in robotic automation. Their unique ability to operate directly alongside workers without barriers has been beneficial for expanding the application of robotic automation. Processes that were not suitable in the past for industrial robots are now being automated by cobots. Cobots have become a vital addition to production floors as manufacturers navigate critical labor shortages.

FANUC has developed two lines of collaborative robots. Their first cobot series was their CR series that originally started with the CR-35iA. FANUC has since added four additional cobots to the CR series. In the past couple of years, FANUC has released a second generation of collaborative robots with their CRX series. The CRX line started with the CRX-10iA and CRX-10iA/L. Last year FANUC added three additional cobots to the line. The FANUC CR and CRX cobot series are designed to compliment one another not necessarily replace each other. All the FANUC cobots in both series feature different payloads and reaches, providing potential users with a greater variety. Below is a comparison of some of the key features from each series.

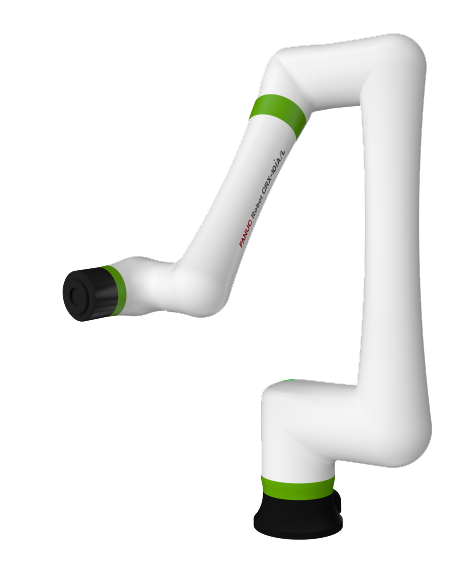

- • Design - The cobots in the CR and CRX lines can easily be distinguished from one another. The CR cobots feature a green exterior while the CRX cobots feature a white epoxy exterior.

- • Payload - Payloads for the CR robots include 4 kg, 7 kg, 15 kg, and 35 kg. The CR-35iA currently is the highest payload cobot. The payloads of the CRX cobots fill in the gaps of the CR cobots with 5 kg, 10 kg, 20 kg, and 25 kg.

- • Reach - Reaches for the CR robots range from 550 mm to 1,813 mm. The FANUC CR-4ia features the shortest reach for those needing a short arm robot. CRX cobots have slightly longer reaches starting at 994 mm and going up to 1,889 mm.

- • Footprint - Both lines feature compact footprints for easier installations. However, the CRX cobots feature a more slender robot design.

- • Controller - The CR-15ia and the other CR cobots are paired with the FANUC R-30iB Plus controller. While the CRX cobots feature FANUC’s R-30iB Mini Plus controller which allows for greater space savings.

- • Programming - Both lines allow for intuitive hand guidance programming. In addition to hand guidance, the CRX-25ia along with the rest of the CRX robots may be programmed with FANUC’s new drag and drop interface tablet.

- • Safety - Both cobot series feature rounded exteriors, smooth finishes, and built-in sensors for collision avoidance. When people or objects are detected the cobot will immediately stop operating. These safety features make barrier-free operation possible while minimizing any safety risk.

- • Maintenance - The CR cobots follow FANUC’s standard preventative maintenance schedule. While the CRX robots offer 8 years zero maintenance on motors, reducers, cables, grease, and sensors.

- • Applications - The CR and CRX cobots can automate many of the same types of applications. These include robotic inspection, material handling, palletizing, packaging, assembly, machine tending, picking, and dispensing. CRX cobots are also capable of welding automation and material removal processes.