The ABB IRB 1600 and the Yaskawa Motoman MH6 are two general purpose robots that can be used to automate a variety of low payload applications. Both of these industrial robots are popular options with their compact footprints and versatility. In fact, the ABB IRB 1600 and the Yaskawa Motoman MH6 share more similarities than they have differences. While their differences may be slight, they are important to consider as they can be the make or break for successful automation.

Similarities of the ABB IRB 1600 and Yaskawa Motoman MH6

Both of these factory robots have the same payload of 6 kg. With a maximum payload capacity of 6 kg, the ABB IRB 1600 and the Yaskawa Motoman MH6 are considered low payload robots and will be limited to handling lighter parts and tooling. Each also offers a higher payload variant of 10 kg for those looking to automate applications with slightly heavier workloads.Another similarity of these robot manipulators is the number of axes they have. Both robots feature 6 axes which allows for a full range of motion. With 6 axes these handling robots will be flexible with their operation and not limited in their range of motion.

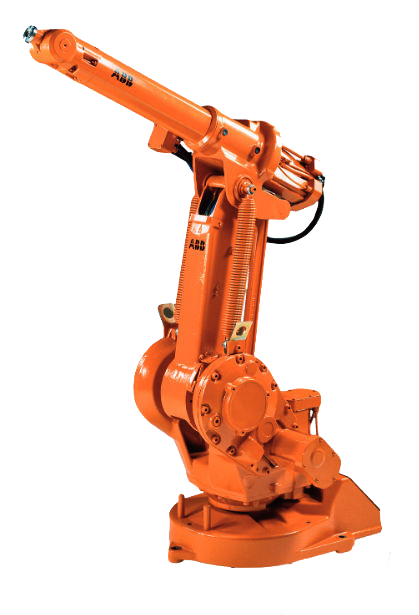

The ABB IRB 1600 and the Yaskawa Motoman MH6 are also both built with an articulated robot structure. This means they both feature a single manufacturing robot arms that is attached to a rotating base. Articulated robots are the most common industrial robot type as they tend to be the most versatile.

Both of these six axis robots can automate the same types of applications and a wide variety of processes at that. Both robots are ideal for automating material handling, packaging, assembly, dispensing, and material removal. In addition to those applications, the IRB 1600 and MH6 can be used as welding robots. Both are capable of automating arc welding, making these some of the most versatile compact robots.

The last similarity between these two industrial robotic arms is that they feature multiple mounting options, making them easier to integrate along production lines. Both robots can be floor mounted, but for those needing to conserve floor space they may be overhead or angle mounted.

Differences Between the ABB IRB 1600 and Yaskawa Motoman MH6

One difference between these robotic manipulators is their mass. The MH6 has a total mass of 130 kg while the IRB 1600 is heavier at 250 kg. With a lighter mass the MH6 may be easier to install, especially if looking to mount overhead or at an angle.Both robots have fast operation speeds but the MH6 is the faster robot out of the two. Those looking to automate a high speed application will have more success from the MH6. The MH6 has a repeatability of +/- 0.08 mm while the IRB 1600 has a repeatability of +/- 0.02 mm.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.