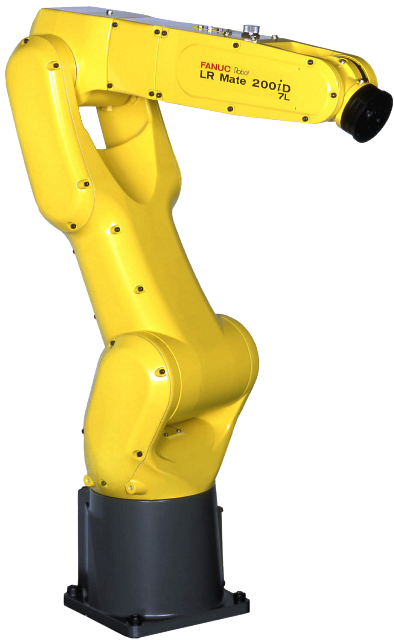

Vision guided robot (VGR) is another term used to describe robotic vision systems. Vision guided robots are industrial robots that have been integrated with cameras and sensors. These cameras and sensors are essentially the “eyes” of the industrial robotic arm, providing visual feedback about the robot’s surrounding work environment and workpieces. The FANUC LR Mate 200ic on its own can successfully automate repetitive tasks. However, integrating the 200ic with a vision system allows it to automate more complex processes with the ability to automatically adapt to variations in part sizes, locations, and shapes. Vision guided robot manipulators can handle variables within applications without the need to be reprogrammed for such changes. Robotic vision can decrease the complexity of factory robots.

Just about any robotic application can benefit from a vision guided robot. Vision systems enhance robot accuracy. Applications involving a mix of parts, location, or a higher level of complexity will likely need a vision guided industrial robot arm. Some of these application types will include:

- • Quality Control - Robotic quality control applications are the most obvious for automation with a vision guided articulated robot. These often involve inspecting parts for any flaws or defects which will need to be done through visual feedback. Vision guided robots can thoroughly inspect parts as their cameras can detect the smallest of flaws.

- • Bin Picking - Bin picking is another application that may require a vision guided industrial robot arm, regardless of whether you are automating a structured or randomized picking process. A vision system allows the Yaskawa Motoman HP6 to accurately select parts, especially if picking from a bin with a mixture of part types.

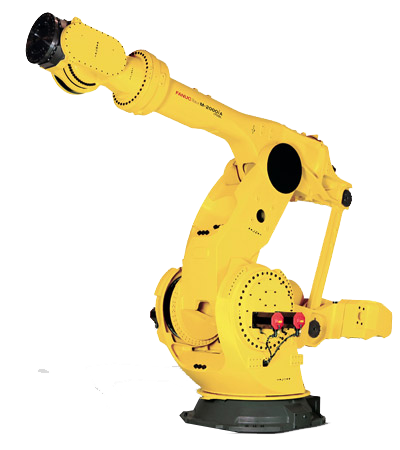

- • Palletizing - Palletizing and depalletizing applications may be less obvious processes for vision guided robot automation. Highly repetitive palletizing typically can be automated by handling robots without vision. For palletizing requiring pattern stacking a vision system will need to be integrated with the FANUC M-410ic/185 or another palletizing robot.

- • Welding - Welding is another application that may not seem like an obvious choice for a vision guided robotic manipulator. Not all welding processes will need a VGR, but those involving complex weld paths or parts with irregular geometries will likely need a arc welding robot integrated with a vision system.

- • Material Removal - Material removal processes such as cutting, deburring, and grinding can benefit from the accuracy of a vision guided six axis robot. These processes require great precision to prevent errors. Vision systems help guide manufacturing robot arms, ensuring consistency and accuracy when removing excess material from workpieces.

- • Assembly - Vision guided robots can improve the quality of assembly applications. Complex assemblies involving irregularly shaped parts or tight tolerances can be automated by vision guided robots. The vision system provides feedback to ensure the accurate assembly of parts and the mitigation of errors.

- • Part Transfer - Vision guided robots are ideal for robotic part transfer applications. They can move parts to varying locations while ensuring parts are not misplaced.

- • Sorting - Sorting applications often involve arranging parts by similarities or in a systematic order. Robot vision is needed in order for sorting robots to be able to identify and group parts accordingly.