FANUC Robots in the Aerospace Industry

Travelling by airplane has become one of the most popular methods of transportation across the globe, with more and more people flying every year. The increased popularity of air travel has caused tremendous growth in the aerospace industry. This increased growth has led to the adoption of robotic automation by aerospace manufacturers in order to keep up with high productivity demands without compromising safety while also helping to reduce costs. Many of these manufacturers are turning to FANUC, the leading robot producer in the world, for their robotic automation needs. The reliability, precision, and efficiency of FANUC robots is helping the aircraft industry produce planes to the highest quality and safety standards.

FANUC Robot Aerospace Applications

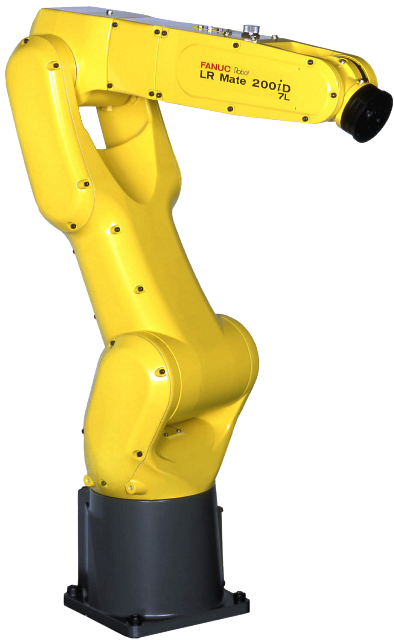

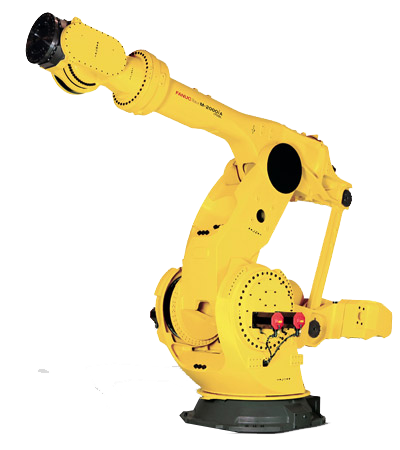

Airplanes are quite large and complex, making them difficult to manufacture efficiently with human workers. FANUC robots take on the challenge of aerospace manufacturing and ease the complexity by performing some of the most key applications with their production.- Drilling - Drilling applications are the most popular choice for automating with FANUC robots like the FANUC M-710ic/50. Cycle time and accuracy are significantly improved with FANUC drilling robots. They are integrated with iRVision to guide them to drill holes in the desired and correct area without creating burrs. Manual drilling can be error prone as well as time consuming since it often requires multiple passes of the drill. Considering the fuselage of a plane needs thousands to millions of holes drilled, it is not feasible to use human workers. FANUC robots are able to complete drills with not only increased speed, but with also only one pass of the drill further decreasing cycle time.

- Painting - FANUC painting robots, such as the FANUC P-250ib, can be commonly found on the production line for an aircraft. Due to the size of planes, manual painting takes an incredible amount of manpower and can be hazardous to workers with the fumes from the paint. FANUC painting robots can be mounted to rails to be able to move several feet across the fuselage while painting, creating a larger work envelope. Their precise movements and accurate paint application reduces overspray and the waste of paint. In the aerospace industry accurate paint coating means more than just aesthetics, it also helps to reduce the weight of the plane.

- Sealing - Airplane manufacturers use FANUC robots to accurately apply beads of sealant along plane components. A FANUC R-2000ib/165F can be used to dispense sealant to the spars of the plane’s wings, which provide load bearing support. Robot sealing accuracy ensures substances such as dust, liquid, gas, and air do not compromise the quality or safety of the aircraft.

- Welding - Robots from FANUC’s arc welding line improve aerospace production with their durable and long-lasting welds. They can be used to weld plane components such as motors that are typically composed of titanium and nickel. Plane metal components require precision welds to ensure safety, which FANUC provides with welding robots like the FANUC Arcmate 120ic.

- Assembly - Plane components such as pumps, motors, and seats are often assembled by FANUC robots. FANUC robots can also be used to assemble larger components with the use of rail or robotic track systems. For example, a FANUC M-900ib/700 mounted to a rail can be used to lay carbon fibers that will then be assembled into a plane’s wings.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.