Robotic automation has become necessary for many manufacturers to stay afloat. Rising costs, labor shortages, and e-commerce have made robotic automation no longer optional but a must in order for companies to remain competitive. For those brand new to robotic automation it may seem overwhelming. Fortunately, an alternative to traditional industrial robots has emerged that can ease the transition to robotic automation and that is the collaborative robot.

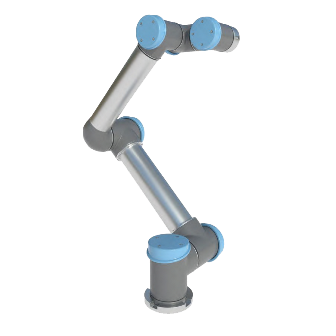

Collaborative robots, also known as cobots, have been one of the biggest trends in robotics over the past several years. They feature small footprints, rounded exteriors, built-in safety sensors, and softer materials. They are incredibly flexible and easy to use which makes them ideal for those new to robotic automation.

- • Low Learning Curve - Collaborative robots have a low learning curve compared to traditional articulated robots. Traditional six axis robot must be programmed through a teach pendant or software program which can take time to learn and become efficient with. Most cobots on the other hand feature lead through programming which is incredibly intuitive. The majority of collaborative robots can be programmed through hand guidance. Simply moving the arm of the Universal UR5 through the waypoints of an application is all that it takes to program it. Hand guidance programming allows even the most novice robot user to operate a cobot with programming taking mere minutes.

- • Fast Setup - Collaborative robots also feature fast setup times. Since cobots are designed with many built-in safety devices they do not require the additional safeguarding equipment that traditional factory robots require. The elimination of extra safety equipment and their intuitive programming allows for quick and easy installation. Cobots can be up and running within just a few hours. Universal cobots, like the UR16e, are especially known for their ease of installation.

- • Designed for Collaborative Operation - What sets the FANUC CR-15ia and other cobots apart from traditional robot manipulators is their ability to operate collaboratively with humans. Cobots are designed to safely operate with and around humans which is why they have many built-in safety features. For those looking to transition to robotic automation but may not be ready to completely automate their production lines collaborative robots may be the solution. Cobots can assist workers, taking over repetitive and dull tasks. Productions can become more efficient with a combination of cobot and human workers.

- • Flexible Automation - Cobots are incredibly flexible with their operation and use. They can automate a variety of applications with quick change over times due to hand programming. Their light weight and compact size makes them easy to move around production floors and redeploy. They can easily fill in where needed. Cobots are ideal for automating small batch runs with multiple changeovers.

- • Built-in Safety Features - Collaborative robotic manipulators feature built-in force sensors, rounded and softer exteriors, along with speed limiting technology. These features minimize and prevent collisions for safe human and cobot interactions. These safety features also eliminate the need for expensive safeguarding equipment. Floorspace and costs are saved which adds to the ease of automating with collaborative robots.