In the past, vision guided robots were in the minority with only about 10% of industrial robots integrated with vision. Fast forward to today, with robot vision systems having become standard for many robotic applications. As the need for robotic automation has grown, so has the complexity of applications needing to be automated. This factor along with the increasing affordability of vision systems has led to the expansion of vision guided articulated robots.

Vision guided industrial robotic arms are industrial robots integrated with cameras and sensors that provide visual feedback to the robot. These robot manipulators are eliminating past barriers of robotic automation and allowing for the automation of more production processes. Why should you consider automating with a vision guided robot? The top reasons are listed below.

Automate Applications with Variables

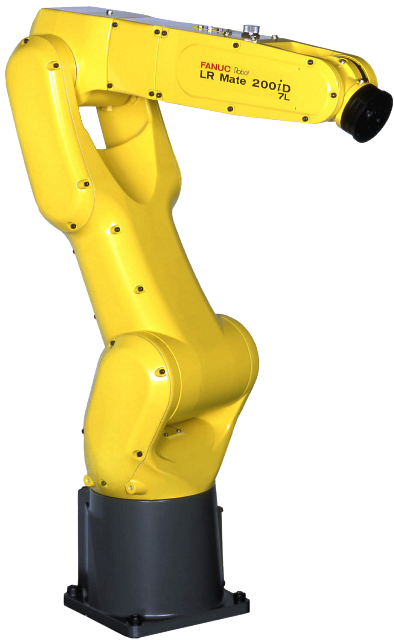

In the past, robotic automation was limited to highly repetitive applications with regular parts. Processes needed to involve the same part types and part locations as factory robots did not have the technology to handle variables. Vision guided robotic manipulators have changed this. The FANUC Lr Mate 200ic with vision can adapt to variables through feedback from its camera system. If part shapes or locations change the robot is able to recognize these changes through the vision system. Vision guided handling robots can automate processes with a mix of part types, various locations, or parts with complex geometries. Vision guided robots can now automate applications involving parts that are not distinctly separated or located in a specific work areas.

Greater Uptime

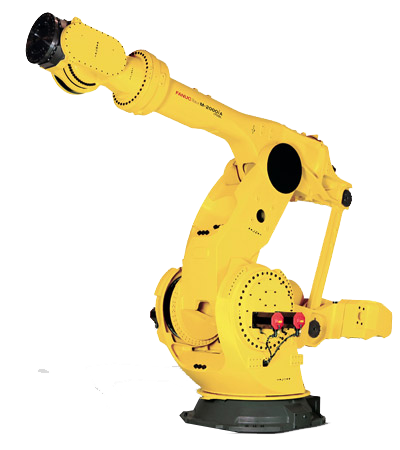

Since vision guided industrial robot arms can automatically recognize and adapt to changes, less programming is required. With traditional six axis robot, programming is needed for every change. This means stopping the robot’s operation until the new program had been implemented, causing downtime. Integrating the ABB 4600-40 with vision decreases programming time since it can adapt to changes on its own. With vision guided robots there is greater uptime, which allows the manufacturing robot arms to operate for longer periods of time, ultimately resulting in higher productivity rates.

Less Human Involvement

While automating with industrial robots reduces human involvement with your productions, automating with a vision guided robot will reduce it even more. With less programming required and the ability of vision guided robots to be able to “see” there work environment, less monitoring of the robotic system is needed. Vision guided robots can operate autonomously. Factories utilizing the lights-out manufacturing method are doing so with vision guided robots. With fewer workers needed for vision guided robots, companies can see a significant reduction in labor expenses.

Greater Accuracy

Industrial robots are designed for accuracy on their own, but adding a vision system can enhance that accuracy. Errors become nonexistent as robots can use visual feedback to enhance their operation. Vision guided robots operate with precision ensuring they do not deviate from an application path. Their ability to adjust to variables on the go, prevents costly errors such as damaged parts or material waste. Vision guided robots can even evaluate and inspect their own work, catching minute defects. Product quality significantly increases with vision guided robots.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.