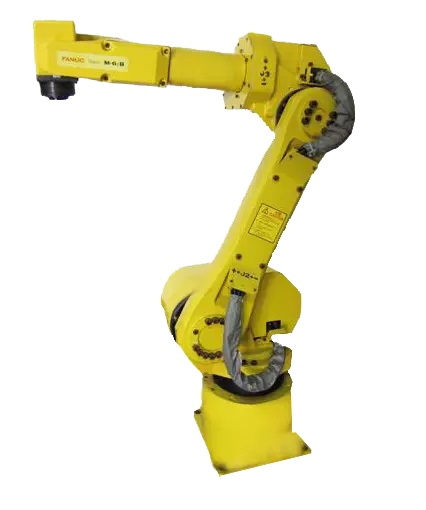

FANUC M-6iB vs Yaskawa Motoman MH6

The FANUC M-6iB and the Yaskawa Motoman MH6 are two popular low payload handling robots. While these assembly robots are quite similar to one another there are some differences that set them apart. These differences may be key to determining whether the FANUC M-6iB or the Yaskawa Motoman MH6 is the best fit for your application. Below is a comparison of some of the key features of both industrial robots.

Structure

Both the FANUC M-6iB and the Yaskawa Motoman MH6 are considered articulated robots. They also share the same axis configuration with six axes. Six-axis articulated robots tend to be the most common in manufacturing since they are incredibly versatile and have a full range of motion. There are few limitations when it comes to mobility for these robot manipulators as six axes allows them to reach a unit of space from every angle.

Payload

Both of these industrial robot arms fall under the low payload robot class. The FANUC M-6iB and Yaskawa Motoman MH6 share a maximum payload capacity of 6 kg. This means these robots are limited to handling light workpieces and tooling. However, the MH6 robotic manipulator features a higher payload variant of 10 kg for those needing a slightly heavier capacity.

Reach

Maximum reach is one of the areas these industrial robot arms are dissimilar to one another. The FANUC M-6iB has a reach of 1,373 mm. While the Yaskawa Motoman MH6 has a reach of 1,422 mm. For those needing a slightly longer reach Yaskawa Motoman MH6 would be best.

Speed

Speed is another area where these factory robots stand out from one another. The Yaskawa Motoman MH6 has the highest speed in its class and therefore will be faster than the FANUC M-6iB. Those looking to automate a high speed application or significantly reduce cycle times should consider the MH6. While the FANUC M-6iB is not as fast as the MH6, automating with it will still result in shorter cycle times and higher productivity.

Repeatability

Both of these robots are incredibly precise. The FANUC M-6iB and the Yaskawa Motoman MH6 share a repeatability of +/- 0.08 mm. Even for the most demanding applications, these robots will be able to operate with the upmost precision.

Mass

The FANUC M-6iB and the Yaskawa Motoman MH6 are very similar in terms of robot mass. The FANUC M-6iB features a robot mass of 135 kg. While the Yaskawa Motoman MH6 has a slightly lighter mass of 130 kg.

Mounting

Both robots offer various mounting options, giving manufacturers greater flexibility when it comes to installation. The FANUC M-6iB can be floor, wall, angle, or overhead mounted. The Yaskawa Motoman MH6 can be floor, wall, or overhead mounted. In addition to various mounting options, both robots feature a compact footprint making them relatively easy to integrate on production floors with minimal space requirements.

Applications

Both robots are primarily used as handling robots but can automate a variety of other applications. The FANUC M-6iB can automate material handling, machine tending, assembly, picking, packing, material removal, cleanroom, and dispensing. The Yaskawa Motoman MH6 can automate material handling, assembly, dispensing, machine tending, packing, and welding.